Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Combination meter / Malfunction in clock

Toyota Corolla (E120): Malfunction in clock

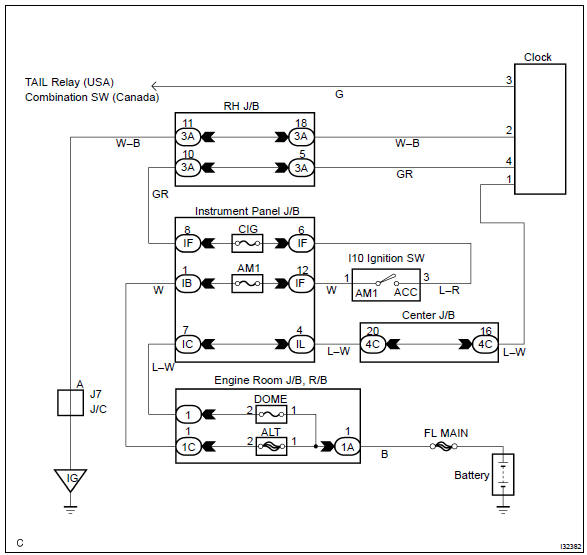

Wiring diagram

Inspection procedure

1 Inspect fuse

- Check the continuity in cig fuse.

- check the continuity in dome fuse.

2 Inspect harness or connector

- Check voltage.

- Remove the clock assy with connector still connected.

- Measure voltage between terminal 1 (+b) of clock assy connector and body ground.

Standard voltage: 10 – 14 v

- turn the ignition switch to acc.

- Measure voltage between terminal 4 (acc) of clock assy connector and body ground.

Standard voltage: 10 – 14 v

- check continuity.

- Check continuity between terminal 2 (e) of clock

assy connector and body ground.

Ok: continuity exists

Replace clock assy

Other materials:

Stabilizer bar rear

Replacement

Hint: components:

1. Remove stabilizer bar rear

Remove the 2 bolts, nuts and stabilizer bar.

2. Install stabilizer bar rear

Install the 2 bolts, nuts and stabilizer bar.

Torque: 195 nvm (1,990 Kgf·cm, 144 ft·lbf)

Hint:

install the stabilizer bar so that the ...

Rear door belt moulding assy lh

Replacement

Hint:

the installation procedures are the removal procedures in reverse

order.

Use the same procedures for the rh side and lh side.

1. Remove rear armrest assy lh

2. Remove power window regulator switch assy rear (w/ power window)

3. Remove rear door window regulator han ...

On–vehicle inspection

1. Inspect front axle hub bearing

remove the front wheel.

separate the front disc brake caliper assy .

remove the front disc.

inspect the bearing backlash.

Using a dial indicator, check the backlash near the

center of the axle hub.

Maximum: 0.05 Mm (0. ...