Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Open in p squib (2nd step) circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

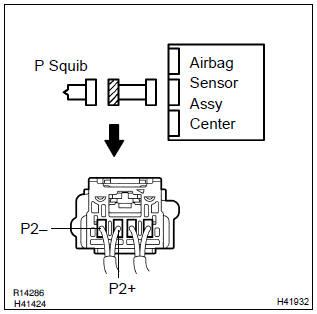

1 Check p squib circuit(airbag sensor assy center – instrument panel passenger airbag assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the instrument panel passenger airbag assy.

- for the connector (on the instrument panel passenger airbag

assy side) between the airbag sensor assy center

and the instrument panel passenger airbag assy, measure

the resistance between p2+ and p2–.

Ok: resistance: below 1Ω

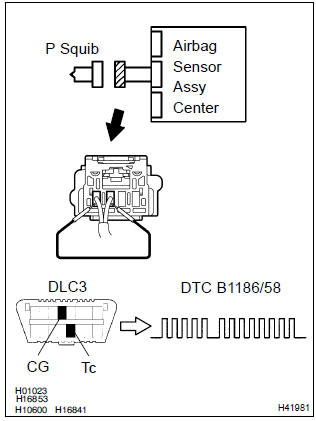

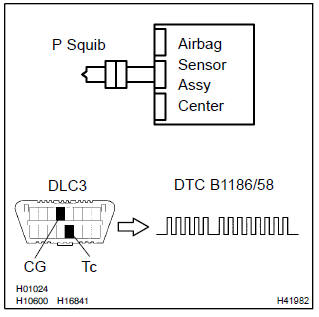

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- using a service wire, connect p2+ and p2– of the connector (on the instrument panel passenger airbag assy side) between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1186/58 is not output.

Hint

: codes other than code b1186/58 may be output at this time, but they are not relevant to this check.

3 Check p squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the instrument panel passenger airbag assy connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1186/58 is not output.

Hint

: codes other than code b1186/58 may be output at this time, but they are not relevant to this check.

Use simulation method to check

Other materials:

Circuit description

The vehicle equipped with abs detects a vehicle speed using the stability

control ecu and wheel speed

sensor. This sensor monitors a wheel rotation speed and sends the signal to the

ecu.

The stability control ecu converts these wheel speed signals into a 4–pulse

signal and outputs it to ...

Checking tires

Check if the treadwear indicators

are showing on the tires.

Also check the tires for uneven

wear, such as excessive wear

on one side of the tread.

Check the spare tire condition

and pressure if not rotated.

New tread

Worn tread

Treadwear indicator

The location of treadwear indicators

is show ...

Aluminum wheel precautions (if equipped)

● Use only Toyota wheel nuts and wrenches designed for use with your aluminum

wheels.

● When rotating, repairing or changing your tires, check that the wheel nuts are

still tight after driving 1000 miles (1600 km).

● Be careful not to damage the aluminum wheels when using tir ...