Toyota Corolla (E120): Inspection procedure

Hint

: start the inspection from step 1 in case of using the hand–held tester and start from step 2 in case of not using hand–held tester.

1 Inspect brake actuator assy

- Select the datalist mode on the hand–held tester.

- check the operation sound of the abs pump motor when operating it

with the hand–held tester.

Ok: the operation sound of the abs pump motor should be heard.

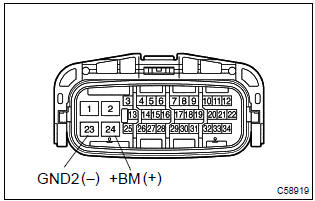

2 Inspect skid control ecu terminal voltage(+bm terminal voltage)

- Disconnect the skid control ecu connector.

- measure the voltage between terminal +bm (24) and

gnd (23) of skid control ecu harness side connector.

Ok: the operation sound of the abs pump motor should be heard.

Replace brake actuator assy

Other materials:

Inspection procedure

1 Check side air bag sensor assy rh

Sst 09843–18040

Connect the negative (–) terminal cable to the battery,

and wait at least for 2 seconds.

turn the ignition switch to on, and wait at least for 20 seconds.

clear the dtc stored in memory .

turn the ignition swi ...

Warning buzzer does not sound (key reminder

warning, light reminder warning)

Wiring diagram

Inspection procedere

1 Check buzzer

Check that all of the warning buzzers sound.

2 Inspect front door courtesy lamp switch assy

3 Inspect un–lock warning switch assy

4 Check harness and connector(between un–lock warning switch

and combination meter as ...

Inspection procedure

1 Inspect transmission wire(s2)

Disconnect the transmission wire connector from the

transaxle.

measure the resistance according to the value(s) in the

table below.

Standard:

2 Check harness and connector(transmission wire – ecm)

Connect the transmission connec ...