Toyota Corolla (E120): Inspection procedure

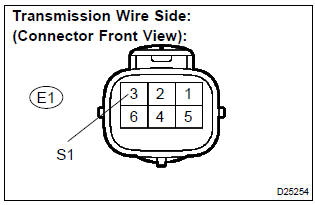

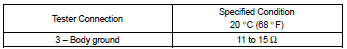

1 Inspect transmission wire(s1)

- Disconnect the transmission wire connector from the transaxle.

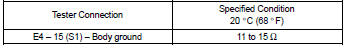

- measure the resistance according to the value(s) in the table below.

Standard:

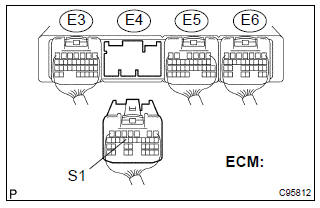

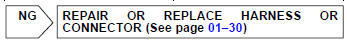

2 Check harness and connector(transmission wire – ecm)

- Connect the transmission connector to the transaxle.

- disconnect the connector from the ecm.

- measure the resistance according to the value(s) in the table below.

Standard:

Replace ecm

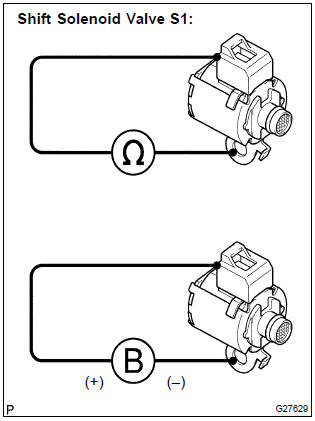

3 Inspect shift solenoid valve(s1)

- Remove the shift solenoid valve s1.

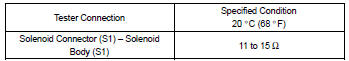

- measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) battery lead to the solenoid connector terminal, and the negative (–) battery lead to the solenoid body for checking the solenoid valve operation.

Standard: the solenoid makes an operating noise.

Repair or replace transmission wire

Other materials:

Replacement

1. Remove engine under cover rh

2. Remove cylinder head cover no.2

Remove the 2 screw, 3 clips and engine under cover.

3. Remove fan and generator v belt

Turn the v–ribbed belt tensioner slowly clockwise and

loosen it. Then, remove the fan and generator v belt and

put back ...

Replacement

Hint:

installation is according to the reverse order of the removal.

1. Remove rear door weatherstrip rh

2. Remove rear door weatherstrip lh

3. Remove rear seat cushion assy (, 72–8)

4. Remove rear seat back assy (fixed type rear seat)

5. Remove separate type rear seat back assy (separate ...

Replacement

Hint: components:

1. Precaution

2. Disconnect battery negative terminal

3. Remove horn button assy

Place the front wheels facing straight ahead.

using a torx socket wrench (t30), loosen the 2 torx

screws until the groove along the screw circumference

catches on the screw ca ...