Toyota Corolla (E120): Circuit description

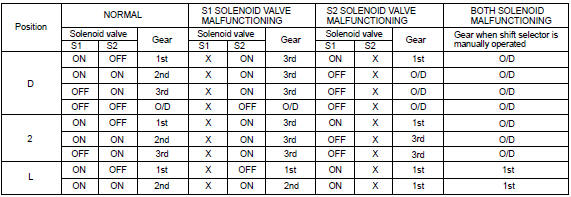

Shifting from 1st to o/d is performed in combination with on and off of the shift solenoid valve s1 and s2 controlled by ecm. If an open or short circuit occurs in either of the solenoid valves, the ecm controls the remaining normal solenoid valve to allow the vehicle to be operated smoothly (fail safe function).

Fail safe function: if either of the solenoid valve circuits develops an open or short, the ecm turns the other solenoid valve on and off to shift to the gear positions shown in the table below. If both solenoids malfunction, hydraulic control cannot be performed electronically and must be done manually.

Manual shifting as shown in the above table must be done (in the case of a short circuit, the ecm stops sending current to the short circuited solenoid).

X: malfunctions

Monitor description

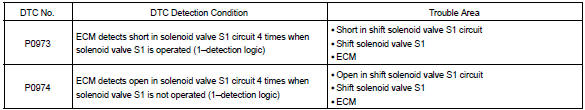

The ecm commands gearshift by turning the shift solenoid valves ”on/off”. When there is an open or short circuit in any shift solenoid valve circuit, the ecm detects the problem and the mil comes on. Illuminating the mil, the ecm performs the fail–safe and turns the other shift solenoid valves in good condition ”on/off” (in case of an open or short circuit, the ecm stops sending current to the circuit.).

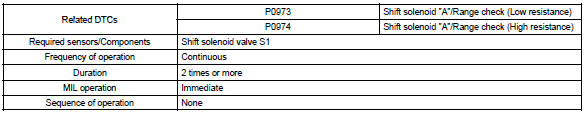

Monitor strategy

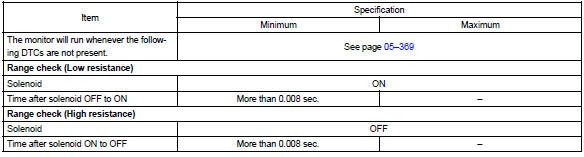

Typical enabling condition

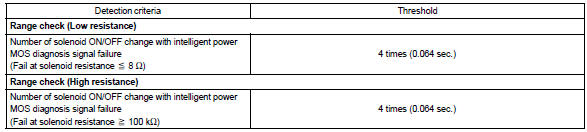

Typical malfunction thresholds

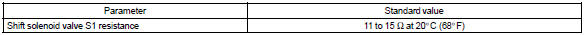

Component operating range

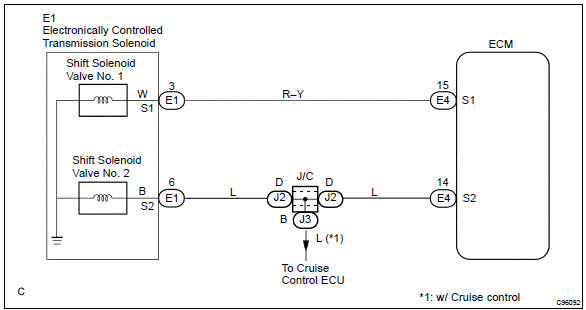

Wiring diagram

Other materials:

Inspection procedure

Hint:

if different dtcs related to different systems that have terminal e2

as the ground terminal are output

simultaneously, terminal e2 may be open.

Read freeze frame data using the hand-held tester or the obd ii scan

tool. Freeze frame data records

the engine conditions when a malf ...

On–vehicle inspection

1. Washer motor

Operation check

pour the water into the washer jar with the washer

motor and the pump installed to the washer jar assy.

Connect the battery (+) to terminal 2 of the washer

motor and the pump, the battery (–) to terminal 1 of

the washer motor and the pump ...

How to proceed with troubleshooting

1 Vehicle brought to workshop

2 Customer problem analysis

3 Check and clear dtc

4 Problem symptom confirmation

Symptom does not occur (go to

step 5)

5 Symptom simulation

6 Dtc check

7 Dtc chart

8 Problem symptoms table

9 Circuit inspection

10 Confirmation test

End

...