Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Seat belt buckle switch (lh)

malfunction / Inspection procedure

Toyota Corolla (E120): Inspection procedure

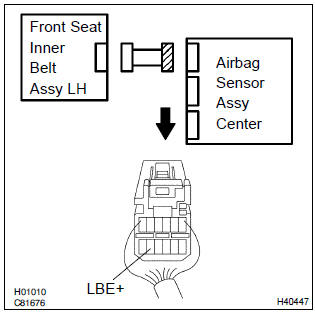

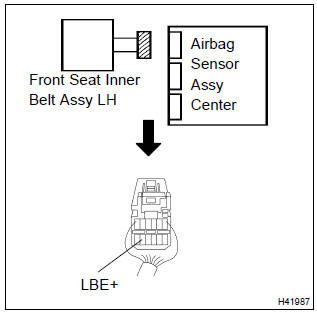

1 Check wire harness(airbag sensor assy center – front seat inner belt assy lh)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the front seat inner belt assy (lh).

- for the connector (on the airbag sensor assy center side)

between the airbag sensor assy center and the front seat

inner belt assy (lh), measure the resistance between

lbe+ and body ground.

Ok: resistance: 1 mw or higher

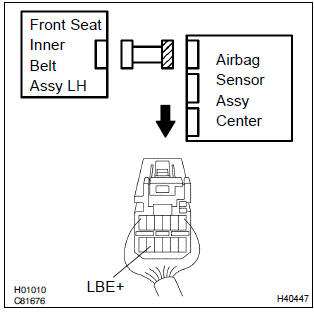

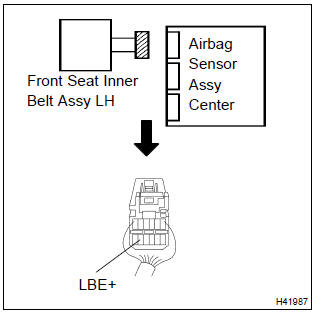

2 Check wire harness(airbag sensor assy center – front seat inner belt assy lh)

- Connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on.

- for the connector (on the airbag sensor assy center side)

between the airbag sensor assy center and the front seat

inner belt assy (lh), measure the voltage between lbe+

and body ground.

Ok: voltage: below 1 v

3 Check front seat inner belt assy lh

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the connector of the front seat inner belt assy (lh).

- unlock the seat belt for the front driver’s seat.

- for the connector (on the airbag sensor assy center side),

measure the resistance between lbe+ and body ground.

Ok: resistance: 1.0 Kw – 1.6 KΩ

4 Check front seat inner belt assy lh

- Lock the seat belt for the front driver’s seat.

- for the connector (on the airbag sensor assy center side),

measure the resistance between lbe+ and body ground.

Ok: resistance: 100 w – 500 Ω

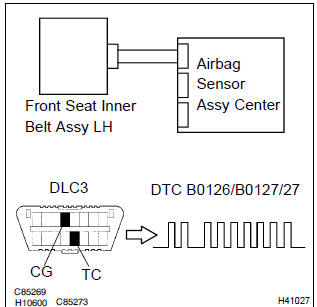

5 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0126/b0127/27 is not output.

Hint

: codes other than code b0126/b0127/27 may be output at this time, but they are not relevant to this check.

Use simulation method to check

Other materials:

Starting system

Inspection

1. Inspect starter assy

Notice:

these tests must be performed within 3 to 5 seconds to

prevent burnout of the coil.

perform the pull–in test.

Remove the nut, then disconnect the lead wire from

terminal c.

Connect the battery to the starter repai ...

Fuel consumption information

Fuel consumption information

can be displayed on the

audio system screen.

System components

Audio system screen

Consumption

■ Trip information

1. Select on the main menu.

2. Select "Trip information".

If a screen other than "Current" is

displayed, select "Current".

The image is an example ...

Inspection procedure

1 Check p squib circuit(airbag sensor assy center – instrument

panel passenger airbag assy)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the instrument panel ...