Toyota Corolla (E120): Overhaul

1. Remove oil pump relief valve

- Remove the oil pump relief valve plug, oil pump relief valve spring and oil pump relief valve.

- Oil pump relief valve plug

- oil pump relief valve spring

- oil pump relief valve

2. Inspect oil pump assy

- Remove 3 screws and oil pump cover.

- Inspect the oil pump relief valve.

- Coat the valve with engine oil and check that it falls smoothly into the valve hole by it own weight.

- inspect the oil pump rotor sub–assembly.

- Coat the oil pump gear set with engine oil and place them into the oil pump body. Check that the rotors revolves smoothly.

- inspect rotor tip clearance.

- Using a feeler gauge, measure the clearance between

the drive and driven rotor tips.

Standard tip clearance: 0.040 – 0.160 Mm (0.0016 – 0.0063 In.)

- Inspect body clearance.

- Using a feeler gauge, measure the clearance between

the driven rotor and body.

Standard body clearance: 0.260 – 0.325 Mm (0.0102 – 0.0128 In.)

- Inspect rotor side clearance.

- Using a feeler gauge and precision straight edge,

measure the clearance between the rotors and precision

straight edge.

Standard side clearance: 0.025 – 0.071 Mm (0.0010 – 0.0028 In.)

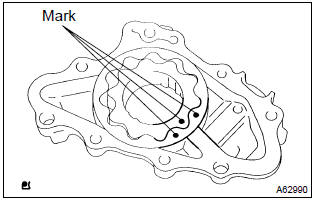

- Install oil pump rotor sub–assembly.

- Coat the oil pump gear set with engine oil and place it into pump body with the marks facing the pump body cover side.

- Install oil pump rotor sub–assembly.

(1) Coat the oil pump gear set with engine oil and place it into pump body with the marks facing the pump body cover side.

3. Install oil pump relief valve

- Install the oil pump relief valve plug, oil pump relief valve

spring and oil pump relief valve.

Torque: 37 nvm (375 Kgf·cm, 27 ft·lbf)

- oil pump relief valve plug

- oil pump relief valve spring

- oil pump relief valve

Other materials:

Circuit description

The variable valve timing (vvt) system includes the ecm, the oil control

valve (ocv) and the vvt controller.

The ecm sends a target ”duty–cycle” control signal to the ocv. This control

signal, applied to the ocv,

regulates the oil pressure supplied to the vvt controller. Camshaft timin ...

When stopping the engine with the shift lever in a position other than P (vehicles

with a continuously variable transmission)

If the engine is stopped with the shift lever in a position other than P, the

engine switch will not be turned off but instead be turned to ACCESSORY mode. Perform

the following procedure to turn the switch off:

1 Check that the parking brake is set.

2 Shift the shift lever to P.

► Vehi ...

Pre–check

1. Selecting compass display mode

the compass switch allows you to select the display or non–display

mode of the compass.

2. Setting zone

deviation between the ”magnetic north” and ”actual north” differs

depending on the location. Therefore,

adjustment of the ...