Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Side airbag sensor assy (rh)

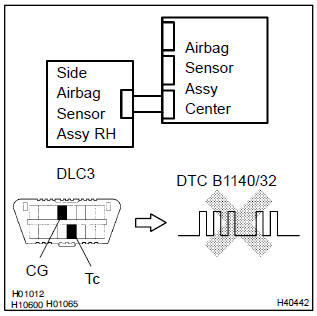

malfunction / Inspection procedure

Toyota Corolla (E120): Inspection procedure

1 Check side air bag sensor assy rh

Sst 09843–18040

- Connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1140/32 is not output.

Hint

: codes other than code b1140/32 may be output at this time, but they are not relevant to this check.

2 Check airbag sensor assy center connector

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- check that the connectors is properly connected to the airbag sensor assy center.

3 Check side airbag sensor assy connector

- Check that the connector is properly connected to the side airbag sensor assy (rh).

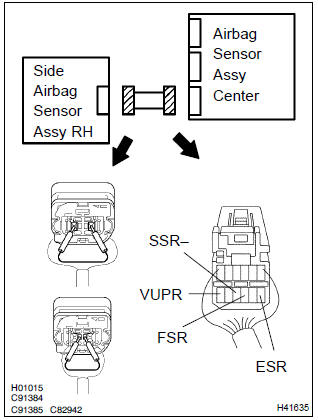

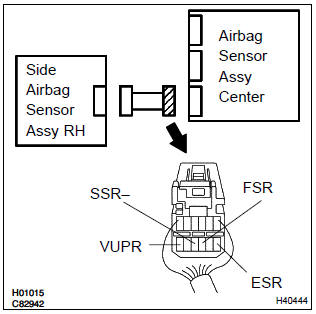

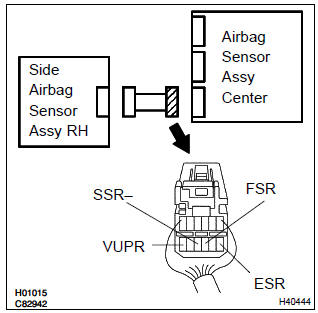

4 Check side airbag sensor assy(rh) circuit(open)(airbag sensor assy center – side airbag sensor assy rh)

Sst 09843–18040

- Disconnect the connectors between the airbag sensor assy center and the side airbag sensor assy rh.

- using a service wire, connect vupr and esr, and fsr and ssr– of the connector (on the side airbag sensor assy side) between the airbag sensor assy center and the side airbag sensor assy (rh).

- for the connector (on the airbag sensor assy center side)

between the side airbag sensor assy rh and the airbag

sensor assy center, measure the resistance between

vupr and esr, and between fsr and ssr–.

Ok: resistance: below 1 Ω

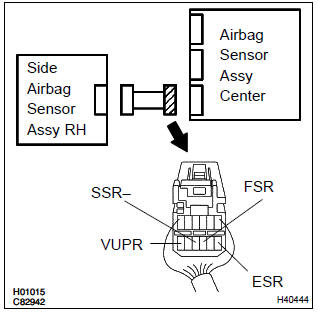

5 Check side airbag sensor assy(rh) circuit(to ground)(airbag sensor assy center – side airbag sensor assy rh)

- Disconnect the connection between vupr and esr, and between fsr and ssr–.

- for the connector (on the airbag sensor assy center side)

between the airbag sensor assy center and the side airbag

sensor assy (rh), measure the resistance between

each terminal of vupr, ssr– and fsr, and body

ground.

Ok: resistance: 1mΩ or higher

6 Check side airbag sensor assy(rh) circuit(airbag sensor assy center – side airbag sensor assy rh)

- For the connector (on the airbag sensor assy center side)

between the airbag sensor assy center and the side airbag

sensor assy (rh), measure the resistance between

vupr and esr, and between fsr and ssr–.

Ok: resistance: 1mΩ or higher

7 Check side airbag sensor assy(rh) circuit(to b+)(airbag sensor assy center – aide airbag sensor assy rh)

- Connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on.

- for the connector (on the airbag sensor assy center side)

between the airbag sensor assy center and the side airbag

sensor assy (rh), measure the voltage between

each terminal of vupr, ssr– and fsr, and body

ground.

Ok: voltage: below 1 v

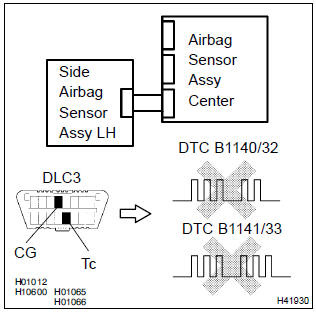

8 Check side air bag sensor assy rh

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the airbag sensor assy center connector.

- interchange the side airbag sensor assy (rh) and lh and connect the connectors to them.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: (a): dtc b1140/32 is not output.

(B): dtc b1141/33 is not output.

9 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Circuit description

When the ignition switch is turned on, battery positive voltage is applied to

the coilwhich closes the contacts

of the efi main relay (marked: efi) and supplies power to terminal +b of the ecm.

This signal causes current to flow to the coil, closing the contacts of the efi

relay and supplyin ...

Overhaul

1. Remove generator pulley

Sst 09820–63010 (09820–06010, 09820–06020)

Hint:

Hold sst 1 – a with a torque wrench, and tighten sst 1

– b clockwise to the specified torque.

Torque: 39 nvm (398 Kgf·cm, 29 ft·lbf)

Notice:

check that sst is secured to the rotor shaft.

...

Adjustment

1. Inspect park/neutral position switch assy

apply the parking brake and turn the ignition switch on.

depress the brake pedal and check that the engine starts only when

the shift lever is set in n or p position

and it does not start in the other position.

check that th ...