Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Ignition coil primary/secondary

circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

1 Perform simulation test

- Clear the dtc

- shuffle arrangement of the ignition coil and igniters.

Notice

: do not shuffle the connectors.

- perform the simulation test.

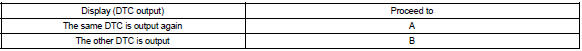

Result:

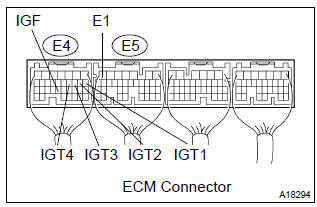

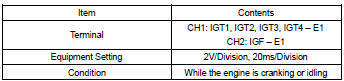

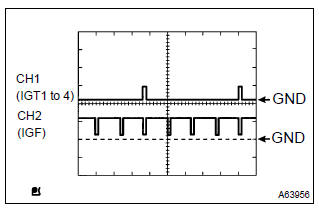

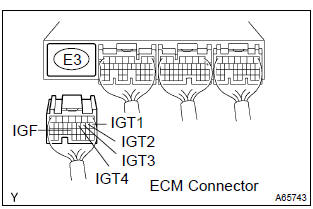

2 Inspect ecm(igt1, igt2, igt3, igt4 and igf signal)

- Inspection using the oscilloscope.

- during cranking or idling, check the waveform between terminals igt1 to igt4 and e1, igf and e1 of the ecm connector.

Standard:

Hint

: correct waveform is as shown in the diagram on the left.

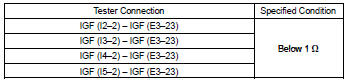

3 Check harness and connector(ignition coil assy – ecm)

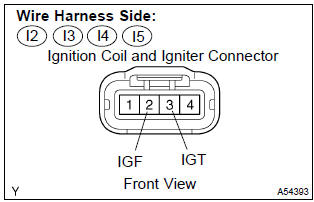

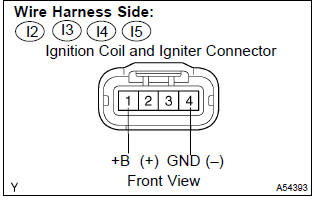

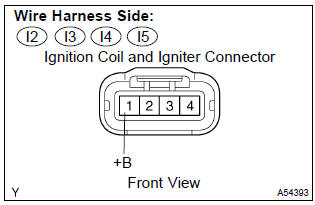

- Disconnect the i2, i3, i4 or i5 ignition coil and igniter connector.

- disconnect the e3 ecm connector.

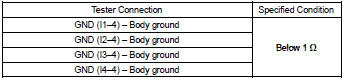

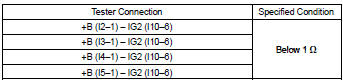

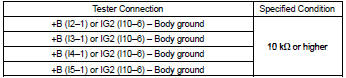

- check the resistance between the wire harness side connectors.

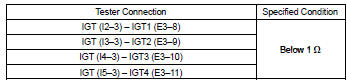

Standard (check for open):

Standard (check for open):

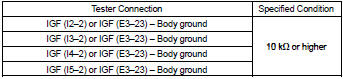

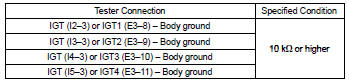

Standard (check for short):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the ignition coil and igniter connector

4 Inspect ignition coil assy(power source)

- Disconnect the i2, i3, i4 or i5 ignition coil and igniter connector.

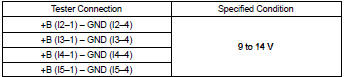

- check the resistance between the wire harness side connectors.

Standard (check for open):

- Turn the ignition switch on position.

- measure the voltage between the terminal of the wire harness side connector and body ground.

Standard:

- Reconnect the ignition coil and igniter connector.

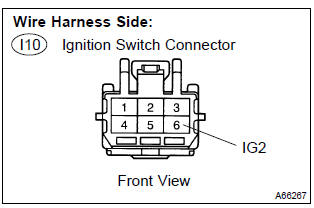

5 Check harness and connector(ignition coil assy – ignition switch)

- Disconnect the i2, i3, i4 or i5 ignition coil and igniter connector.

- disconnect the i10 ignition switch connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the ignition coil and igniter connector.

- reconnect the ignition switch connector.

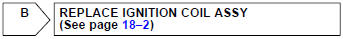

Replace ignition coil assy

Other materials:

Evap monitor (vacuum pressure monitor) (continued)

Preconditions

The monitor will not run unless:

mil is off.

Fuel level is approximately 1/2 to 3/4.

Altitude is 7800 feet (2400 m) or less.*

Engine coolant temperature (ect) is between 40°f and 95°f (4.4 °C and 35

°C).

Intake air temperature (iat) is between 40°f and 95 ...

Diagnostic trouble code chart

The inspection procedures are shown in the table below. This table allows

efficient and accurate troubleshooting

using the diagnostic trouble codes displayed in the diagnostic trouble code

chart. Proceed with

troubleshooting in accordance with the inspection procedures listed in the

diagnost ...

Circuit description

The camshaft position sensor (g22+ signal) consists of a magnet, iron core

and pickup coil.

The g22+ signal plate has 3 teeth on its outer circumference and is installed on

the camshaft timing pulley.

When the camshafts rotate, the protrusion on the signal plate and the air gap on

the pi ...