Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Ignition coil primary/secondary

circuit / Circuit description

Toyota Corolla (E120): Circuit description

Hint

:

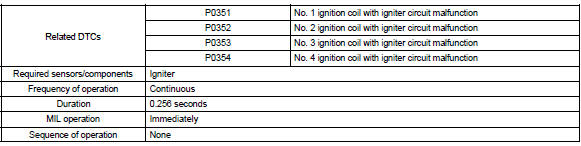

- these dtcs indicate a malfunction related to the primary circuit.

- If dtc p0351 is displayed, check the no.1 Ignition coil with igniter circuit.

- If dtc p0352 is displayed, check the no.2 Ignition coil with igniter circuit.

- If dtc p0353 is displayed, check the no.3 Ignition coil with igniter circuit.

- If dtc p0354 is displayed, check the no.4 Ignition coil with igniter circuit.

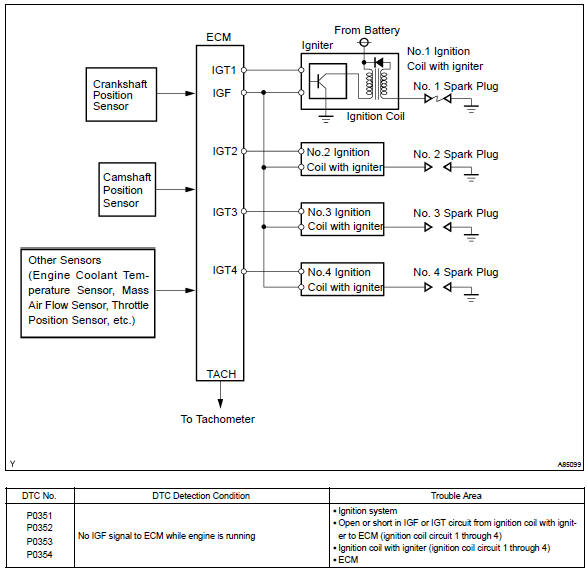

A direct ignition system (dis) is used on this vehicle. The dis improves the ignition timing accuracy, reduces high–voltage loss, and enhances the overall reliability of the ignition system by eliminating the distributor.

The dis is a 1–cylinder ignition system which ignites one cylinder with one ignition coil. In the 1–cylinder ignition system, the one spark plug is connected to the end of the secondary winding. High voltage generated in the secondary winding is applied directly to the spark plug. The spark of the spark plug passes from the center electrode to the ground electrode.

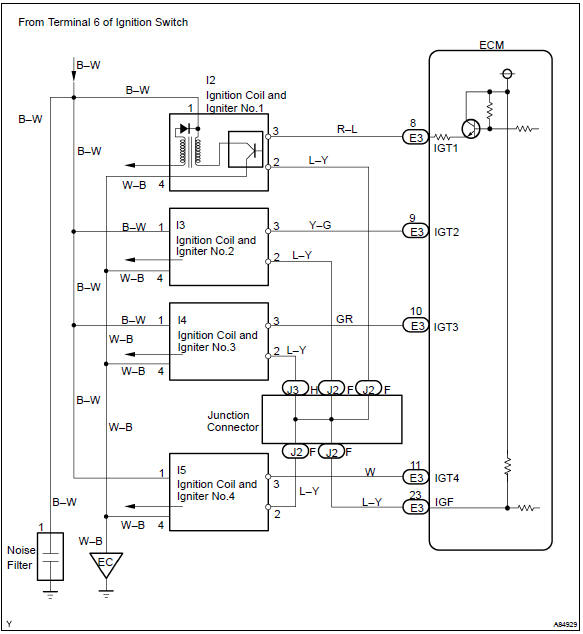

The ecm determines the ignition timing and outputs the ignition signals (igt) for each cylinder. Using the ignition (igt) signal, the ecm turns on and off the power transistor inside the igniter and this switches on and off the current to the primary coil. When the current flow to the primary coil is cut off, high–voltage is generated in the secondary coil and this voltage is applied to the spark plugs to spark inside the cylinders.

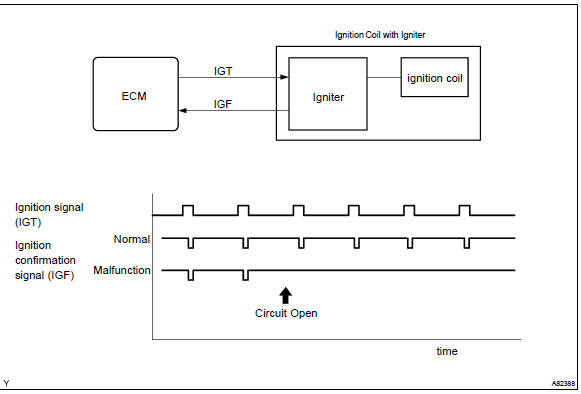

As the ecm cuts the current to the primary coil, the igniter sends back the ignition confirmation (igf) signal for each cylinder ignition to the ecm.

Monitor description

If the ecm does not receive the ignition confirmation signal (igf) after sending the ignition signal (igt), it interprets this as a fault in the igniter and sets a dtc.

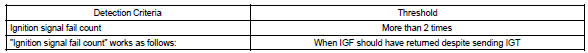

Monitor strategy

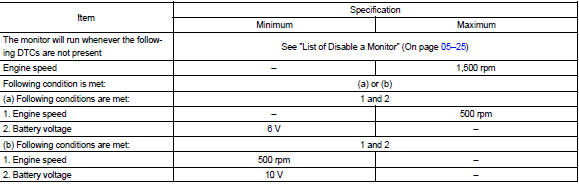

Typical enabling conditions

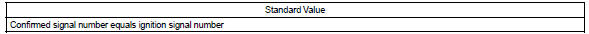

Typical malfunction thresholds

Component operating range

Wiring diagram

Other materials:

Towing your vehicle with 4 wheels on the ground

To prevent damage to your vehicle, perform the following procedures before towing.

1 Shift the shift lever to N.

2 Turn the engine switch to the “ACC” position (without a smart key system) or

ACCESSORY mode (with a smart key system).

(, 166) Ensure that the audio system and other powered de ...

Warning buzzer does not sound (key reminder

warning, light reminder warning)

Wiring diagram

Inspection procedere

1 Check buzzer

Check that all of the warning buzzers sound.

2 Inspect front door courtesy lamp switch assy

3 Inspect un–lock warning switch assy

4 Check harness and connector(between un–lock warning switch

and combination meter as ...

Playing audio CDs and MP3/WMA discs

CD player operation

Insert a disc or press to begin

listening to a disc.

1 Power

2 Volume

3 Eject a disc

4 Repeat play

5 Random playback 6 Select a track/file or display

track/folder list

7 Displays text message

8 Playback

9 Select a folder (MP3/WMA discs only), fast-forward or revers ...