Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Crankshaft position sensor ”a”

circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

:

- perform the troubleshooting of dtc p0335 first. If no trouble is

found, troubleshoot the engine mechanical

systems.

Read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

- Read value of hand–held tester or obd ii scan tool

(a) connect the hand–held tester or the obd ii scan tool to the dlc3.

(B) start the engine and push the hand–held tester or the obd ii scan tool main switch on.

(C) select the item ”diagnosis / enhanced obd ii / data list / all / engine spd”.

- The engine speed can be confirmed in data list using the hand–held tester or obd ii scan tool. If there is no ne signals from the crankshaft position sensor despite the engine revolving, the engine speed will be indicated as zero. If voltage output of the crankshaft position sensor is insufficient, the engine speed will be indicated as lower prm (than the actual rpm).

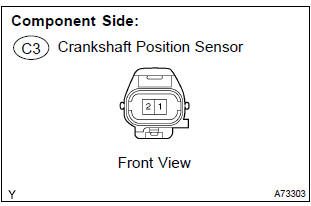

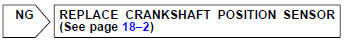

1 Inspect crankshaft position sensor(resistance)

- Disconnect the c43crankshaft position sensor connector.

- measure the resistance between the terminals of the crankshaft position sensor connector.

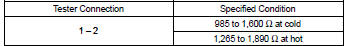

Standaed:

Notice

: ”cold” and ”hot” shown above mean the temperature of the coils themselves. ”Cold” is from –10 c (14 f) to 50 c (122 f) and ”hot” is from 50 c (122 f) to 100 c (212 f).

- reconnect the crankshaft position sensor connector.

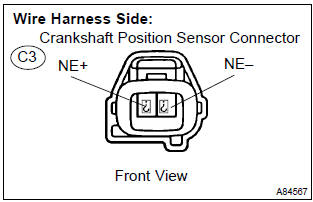

2 Check harness and connector(crankshaft position sensor – ecm)

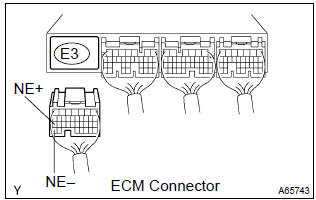

- Disconnect the c3 crankshaft position sensor connector.

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

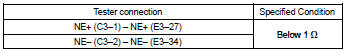

Standard (check for open):

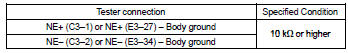

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the crankshaft position sensor connector.

3 Check sensor installation(crankshaft position sensor)

- Check the crankshaft position sensor installation .

4 Check crankshaft position sensor plate(teeth of sensor plate(crankshaft))

- Check the teeth of the sensor plate.

Replace ecm

Other materials:

Overhaul

Caution:

wear the gloves, because the cutting surface of the seat back frame and seat

adjuster may injure

your hand.

Hint:

tape the screwdriver tip before use when prying parts.

1. Disconnect battery negative terminal

Caution:

wait for 90 seconds after disconnecting the battery terminal a ...

Monitor description

The battery supplies electricity to the ecm even when the ignition switch is

off. This electricity allows the

ecm store data such as dtc history, freeze frame data, fuel trim values, and

other data. If the battery voltage

falls below a minimum level, the ecm will conclude that there is a fault ...

Starting the engine

1 Continuously variable transmission: Ensure that the shift lever is in P and

depress the brake pedal.

Manual transmission: Shift the shift lever to N and depress the clutch pedal.

2 Touch the Toyota emblem side of the electronic key to the engine switch.

When the electronic key is detected, a ...