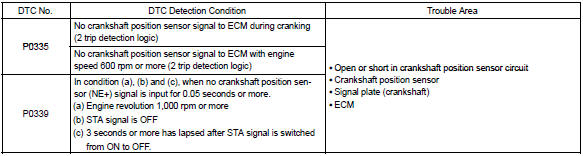

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Crankshaft position sensor ”a”

circuit / Circuit description

Toyota Corolla (E120): Circuit description

The crankshaft position sensor (ne signal) consists of a magnet, iron core and pickup coil.

The ne signal plate (crankshaft position sensor plate) has 34 teeth and is installed on the crankshaft. The ne signal sensor generates 34 signals for each engine revolution. This sensor monitors a plate (timing rotor) located on the crankshaft timing pulley and is used by the ecm to detect crankshaft angle and engine speed (rpm/ne). As the crankshaft timing pulley rotates through an engine revolution, this sensor communicates the rotation of the ne signal plate as a pulse signal to the ecm. Based on the signal, the ecm controls fuel injection time and ignition timing.

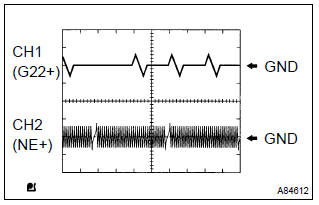

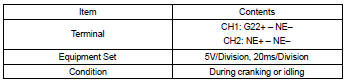

Reference: inspection using the oscilloscope.

Hint

: the correct waveform is as shown on the left.

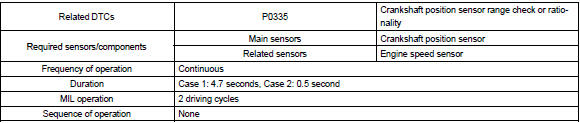

Monitor description

If there is no signal from the crankshaft sensor despite the engine revolving, the ecm interprets this as a malfunction of the sensor.

Monitor strategy

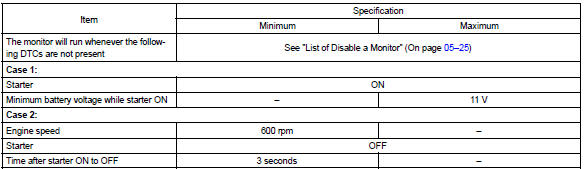

Typical enabling conditions

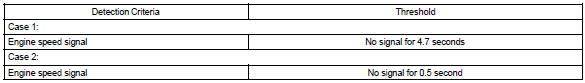

Typical malfunction thresholds

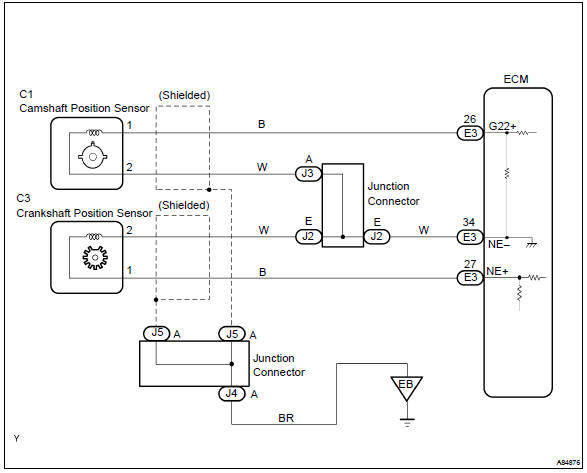

Wiring diagram

Other materials:

Overhaul

1. Remove bench type rear seat cushion assy

Disengage the 2 clamps, and then remove the seat cushion.

2. Remove bench type rear seat back assy

remove the headrests.

remove the 2 bolts and seat back.

3. Remove bench type rear seat cushion

cover

remove the ho ...

On–vehicle inspection

1. Check fuel pump operation

Connect the hand–held tester to the dlc3.

turn the ignition switch on and hand–held tester main

switch on.

Notice:

do not start the engine.

select the active test mode on the hand–held tester.

please refer to the hand–held te ...

Steering column

Preparation

Sst

Recomended tools

Equipment

...