Toyota Corolla (E120): Inspection

1. Fuel injector assy

- Inspect injector resistance.

- Using an ohmmeter,measure the resistance between

the terminals.

Resistance: 13.4 – 14.2 Ω at 20 c (68 f)

- Inspect injector inspection

Caution

: keep injector clear of sparks during the test.

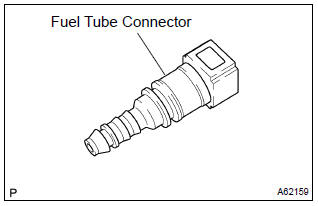

- Purchase a new fuel tube, and take out the fuel tube connector from its tube.

Hint

: part no. 23901–0D010

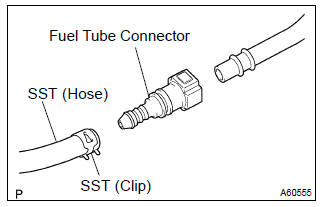

- Connect sst and fuel tube connector to the fuel

pipe.

Sst 09268–41047 (90467–13001, 95336–08070)

Caution

: perform connecting operations of the fuel tube connector (quick type) after observing the precautions.

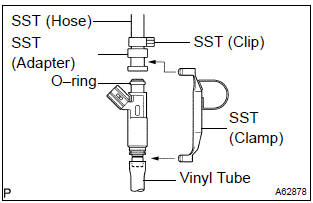

- Install an o–ring to the fuel injector.

- Connect sst (union and hose) to fuel the injector, and hold the fuel injector to prevent gasoline from splashing out. sst 09268–41047 (90467–13001, 95336–08070, 09268–41110, 09268–41300)

- Put the fuel injector into a graduated cylinder.

Hint

: install a suitable vinyl tube onto the injector to prevent gasoline from splashing out.

- Operate the fuel pump.

- Connect sst to the connector of fuel injector.

Sst 09842–30080

- connect sst to the battery for 15 seconds, and

measure the injection volume with a graduated cylinder.

Test the each fuel injector 2 or 3 time.

Injection volume: 60 – 73 cm3 (3.7 – 4.5 Cu in.) Per 15 seconds difference between each injector: 13 cm3 (0.8 Cu in.) Or less

- Inspect leakage

- in the condition above, disconnect the test probes

of the from the battery, and check the fuel leakage

from the fuel injector.

Fuel drop: 1 drop or less per 12 minutes

2. Fuel pump

- Inspect fuel pump resistance.

- Using an ohmmeter, measure the resistance between

the terminals.

Resistance: 0.2 – 3.0 W at 20 c (68 f)

- inspect fuel pump operation

- apply battery voltage to both terminals. Check that the pump operates.

Notice

:

- these tests must be done quickly (within 10 seconds) to prevent the coil from burning out.

- Keep fuel pump as far away from the battery as possible.

- Always do the switching at the battery side.

Other materials:

Registering a Bluetooth® device

Before using the Bluetooth® audio/phone, it is necessary to register a Bluetooth®

device in the system. You can register up to 5 Bluetooth® devices.

How to register a Bluetooth® device

1 Press and select “Bluetooth*”

using .

2 Press and select “BT Pairing”

using .

A passkey w ...

Horn

To sound the horn, press on or close to the

mark.

CAUTION

■Caution while driving

Do not adjust the steering wheel while driving.

Doing so may cause the driver to mishandle the vehicle and cause an accident,

resulting in death or serious injury.

■After adjusting the steering wh ...

Installing child restraints

Follow the child restraint system manufacturer's instructions.

Firmly secure child restraints to the seats using the LATCH anchors or a seat

belt. Attach the top tether strap when installing a child restraint.

The lap/shoulder belt can be used if your child restraint system is not compatible ...