Toyota Corolla (E120): On–vehicle inspection

1. Check fuel pump operation

- Connect the hand–held tester to the dlc3.

- turn the ignition switch on and hand–held tester main

switch on.

Notice

: do not start the engine.

- select the active test mode on the hand–held tester.

- please refer to the hand–held tester operator’s manual for further details.

- if you have no hand–held tester, connect the positive (+) lead form the battery to terminal 4 of the connecter, and the negative (–) lead to terminal 5.

Notice

:

- these tests must be done quickly (within 10 seconds) to prevent the coil burning out.

- Keep the fuel pump as far away from the battery as possible.

- Always do the switching at the battery side.

2. Check fuel pressure

- Prepare for inspection.

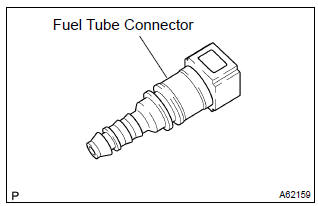

- Purchase a new fuel tube, and take out the fuel tube connector from its tube.

Hint

: part no. 23901–0D010

- work for prevent gasoline from spilling out.

- disconnect the efi fuel pipe clamp.

- disconnect the fuel tube from the fuel main tube.

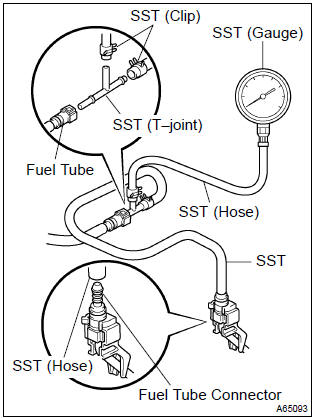

- Install sst (pressure gauge) as shown in the illustration

by using the sst and fuel tube connector.

Sst 09268–41047 (90467–13001, 95336–08070), 09268–45014 (09268–41200, 09268–41220, 09268–41250, 90467–13001)

- wipe off any splattered gasoline.

- ) start the engine.

- measure the fuel pressure at idle.

Fuel pressure: 304 – 343 kpa (3.1 – 3.5 Kgfvcm2, 44 – 50 psi)

- stop the engine.

- check that the fuel pressure remains as specified for 5

minutes after the engine has stopped.

Fuel pressure:

147 kpa (1.5 Kgfvcm2, 21 psi) or more

If pressure is not as specified, check the fuel pump, pressure regulator and/or injectors.

- after checking fuel pressure, disconnect the negative (–) terminal cable from the battery and carefully, remove the sst and fuel tube connector to prevent gasoline from the splashing.

- reconnect the fuel tube to fuel main tube.

- install the efi fuel pipe clamp.

- check fuel leak.

Other materials:

Circuit description

Refer to dtc p0335

Dtc no.

Dtc detection condition

Trouble area

P0016

Deviation in crankshaft position sensor signal and camshaft

position sensor signal (2 trip detection logic)

Mechanical system (timing chain has jumped a tooth, chain

stretch ...

Body panel undercoating areas

Apply pastar uwe or pastar uc to the chassis, floor underside, sheet metal

fitting weld points of the body, and

inside of the wheel house to prevent rust and noise, as well as protect the body

from flying rocks.

Hint:

work must be performed while wearing the appropriate protective ...

No sound is heard from speaker in all modes

Wiring diagram

Inspection procedure

1 Check lcd (liquid crystal display) for lighting

Lcd illumination check

turn the ignition switch acc.

Turn the radio receiver assembly on.

Standard: lcd illumination of the radio receiver assembly light.

2 Control fader and ...