Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position ”a” actuator

circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: read freeze frame data using the hand–held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

Hand–held tester

1 Perform active test by hand–held tester(operate ocv)

- Connect the hand–held tester to the dlc3.

- start the engine and warm it up.

- turn the ignition switch on and push the hand–held tester main switch on.

- select the item ”diagnosis / enhanced obd ii / active test / vvt ctrl b1”.

- check the engine speed when operating the oil control valve (ocv) by the hand–held tester.

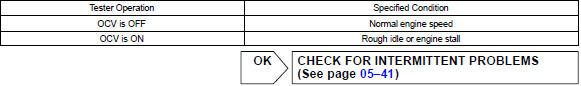

Standard:

2 Inspect camshaft timing oil control valve assy(ocv)

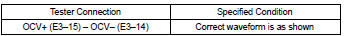

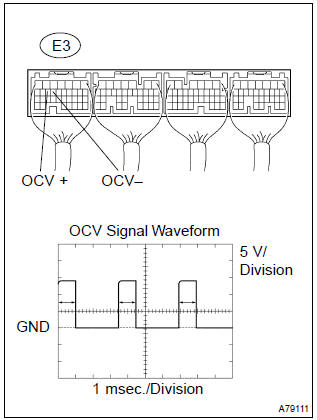

3 Inspect ecm(ocv signal)

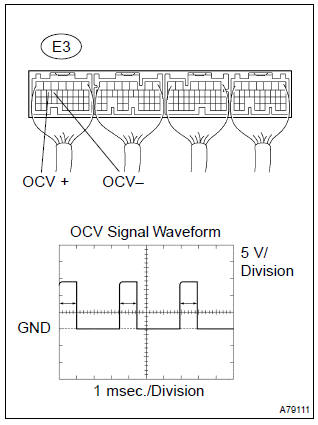

- Inspection using the oscilloscope.

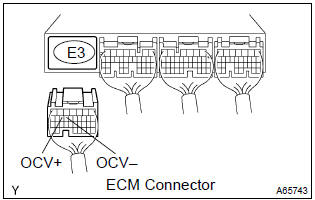

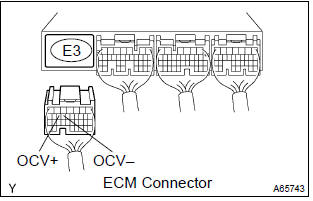

- during idling, check the waveform between the terminals of the e3 ecm connector.

Standard:

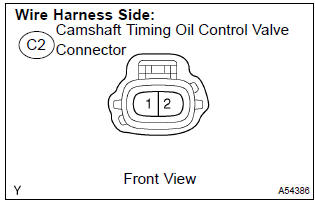

4 Check harness and connector(camshaft timing oil control valve (ocv) – ecm)

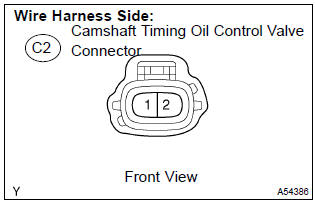

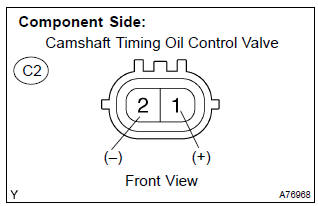

- Disconnect the c2 camshaft timing oil control valve connector.

- disconnect the e3 ecm connector.

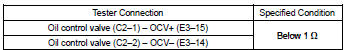

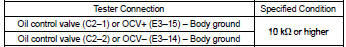

- check the resistance between the wire harness side connectors.

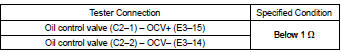

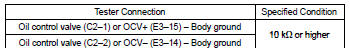

Standard (check for open):

Standard (check for short):

- Reconnect the camshaft timing oil control valve connector.

- reconnect the ecm connector.

Check for intermittent problems

Obdii scan tool (excluding hand–held tester):

1 Inspect camshaft timing oil control valve assy(operate ocv)

- Disconnect the c2 camshaft timing oil control valve connector.

- apply positive battery voltage between the terminals of the camshaft timing oil control valve.

- check the engine speed.

Standard

: engine speed is rough idle or engine is stalled.

- reconnect the camshaft timing oil control valve connector.

2 Inspect ecm(ocv signal)

- Inspection using the oscilloscope.

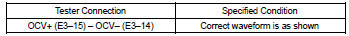

- during idling, check the waveform between the terminals of the e3 ecm connector.

Standard:

3 Check harness and connector(camshaft timing oil control valve (ocv) – ecm)

- Disconnect the c2 camshaft timing oil control valve connector.

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the camshaft timing oil control valve connector.

- reconnect the ecm connector.

Check for intermittent problems

Other materials:

Registering a new contact to the contact list

New contact data can be registered. Up to 4 numbers per person can be registered.

For PBAP compatible Bluetooth® phones, this function is available when “Automatic

Contact/History Transfer” is set to off.

1 Select “New Contact”.

2 Enter the name and select “OK”.

3 Enter the phone ...

Listening to a USB memory device

Connecting a USB memory device enables you to enjoy music from the vehicle

speakers.

Touch “USB” on the audio source selection screen.

Connecting a USB memory device

Audio control screen

Pressing the “AUDIO” button displays the audio control screen from any screens

of the selected so ...

Using the radio (Multimedia system)

Radio operation

Select “AM” or “FM” on the audio source selection screen to begin listening

to the radio.

Audio control screen

Pressing the “AUDIO” button displays the audio control screen from any screens

of the selected source.

1 Audio source selection screen appears

2 Preset ...