Toyota Corolla (E120): Circuit description

The shift solenoid valve sl is turned ”on” and ”off” by signals from the ecm in order to control the hydraulic pressure operation, the lock–up relay valve, which then the controls operation of the lock–up clutch.

Fail safe function: if the ecm detects a malfunction, it turns the shift solenoid valve sl off.

Monitor description

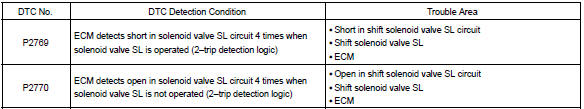

Based on the signals from the throttle position sensor, the airflow meter and the crankshaft position sensor, the ecm sends a signal to the sl solenoid valve to regulate the hydraulic pressure and provide smoother gearshifts. The shift–solenoid valve sl responds to commands from the ecm. The valve controls the lock–up relay valve to perform the torque–converter lock–up function. If the ecm detects an open or short circuit for shift–solenoid sl, it will illuminate the mil.

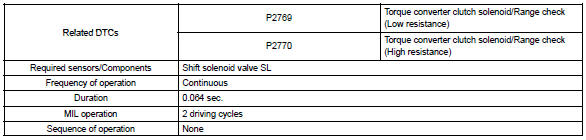

Monitor strategy

Typical enabling condition

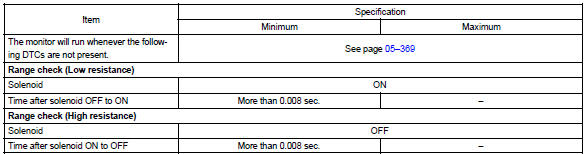

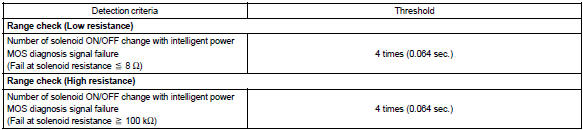

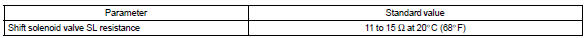

Typical malfunction thresholds

Component operating range

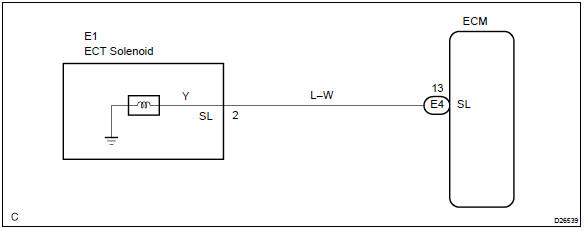

Wiring diagram

Other materials:

Inspection procedure

Hint:

if dtcs p0115, p0116, p0117, p0118 and p0125 are output

simultaneously, the engine coolant temperature

sensor circuit may be open or short. Perform the troubleshooting of dtc

p0115, p0117 or

p0118 first.

Read freeze frame data using the hand-held tester or the obd ii scan

to ...

Diagnostic trouble code chart

If a dtc is displayed during the dtc check, check the circuit listed in the

table below and proceed to the

page given.

* :● ... Mil light up

...

Keys

The following keys are provided

with the vehicle.

Type A

Keys (without a wireless

remote control function)

Key number plate

Type B

Keys (with a wireless remote

control function)

Operating the wireless remote control

function

Key number plate

Type C

Electronic keys

Operating the sm ...