Toyota Corolla (E120): Inspection procedure

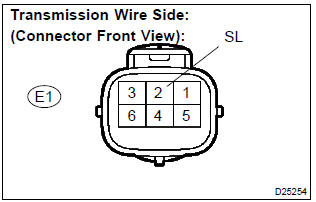

1 Inspect transmission wire(sl)

- Disconnect the transmission wire connector from the transaxle.

- measure the resistance according to the value(s) in the table below.

Standard:

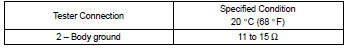

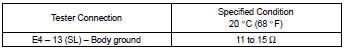

2 Check harness and connector(transmission wire – ecm)

- Connect the transmission wire connector.

- disconnect the ecm connector.

- measure the resistance according to the value(s) in the table below.

Standard:

Replace ecm

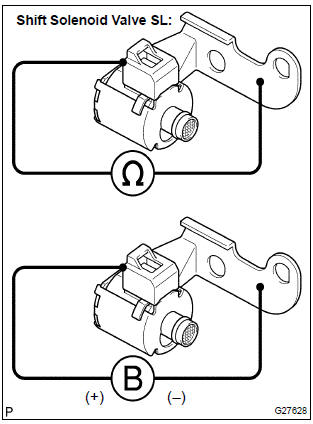

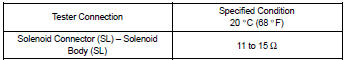

3 Inspect shift solenoid valve(sl)

- Remove the shift solenoid valve sl.

- measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) battery lead to the solenoid connector terminal, and the negative (–) battery lead to the solenoid body for checking the solenoid valve operation.

Standard: the solenoid valve makes an operating noise.

Repair or replace transmission wire

Other materials:

Checking and adding the

brake fluid

■ Checking fluid level

The brake fluid level should be

between the "MAX" and "MIN"

lines on the tank.

■ Adding fluid

1. Slide and lift up the rubber

strip to partly remove it as

shown.

2. Disconnect the claws and

remove the service cover.

3. Remove the reservoir cap.

4. Add brake fluid slowl ...

Rear wheel alignment

Inspection

1. Inspect tire

2. Measure vehicle height

Notice:

before inspecting the wheel alignment, adjust the vehicle height to the

specified value.

3. Inspect toe–in

Toe–in:

usa, canada:

Mexico:

If the toe–in is not within the specified value, inspect and replace

the susp ...

Customization

Customizable features

Your vehicle includes a variety of electronic features that can be personalized

to suit your preferences. Programming these preferences requires specialized equipment

and may be performed by your Toyota dealer.

Customizing vehicle features

■ Changing by using the n ...