Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Electronic controlled automatic transaxle / Shift solenoid ”a” performance

(shift solenoid valve s1)

Toyota Corolla (E120): Shift solenoid ”a” performance (shift solenoid valve s1)

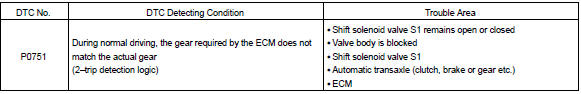

Dtc p0751 shift solenoid ”a” performance (shift solenoid valve s1)

System description

The ecm uses signals from the vehicle speed sensor and crankshaft position sensor to detect the actual gear position (1st, 2nd, 3rd or o/d gear).

Then the ecm compares the actual gear with the shift schedule in the ecm memory to detect the mechanical trouble of the shift solenoid valves, the valve body or automatic transaxle (clutch, brake or gear etc.).

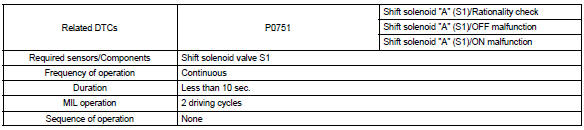

Monitor description

The ecm commands gear shifts by turning the shift solenoid valves ”on/off”. According to the input shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ecm detects the actual gear position (1st, 2nd, 3rd or o/d gear position). When the gear position commanded by the ecm and the actual gear position are not same, the ecm illuminates the mil.

Monitor strategy

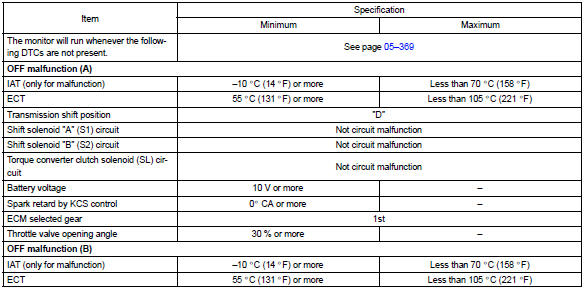

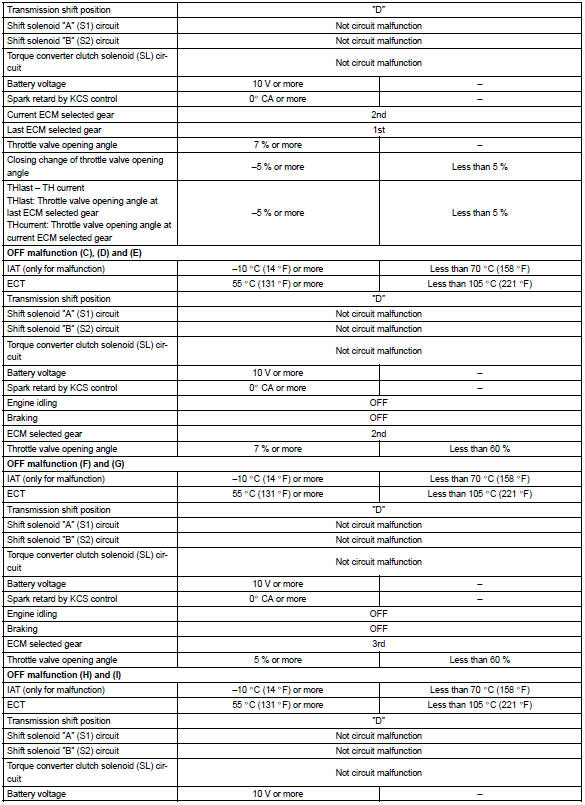

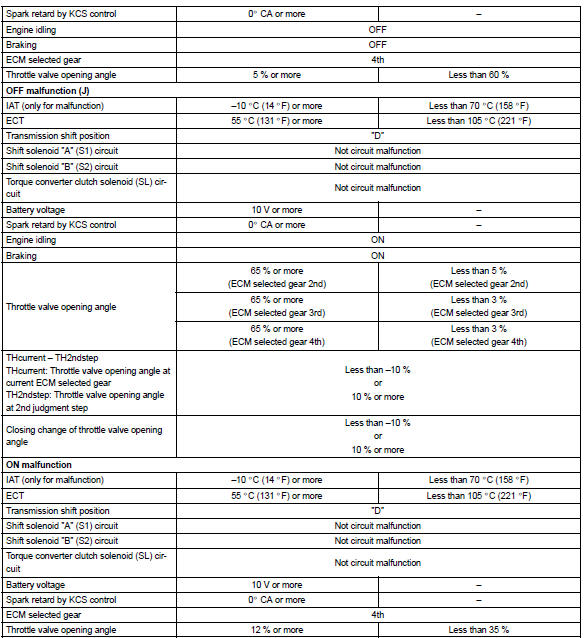

Typical enabling conditions

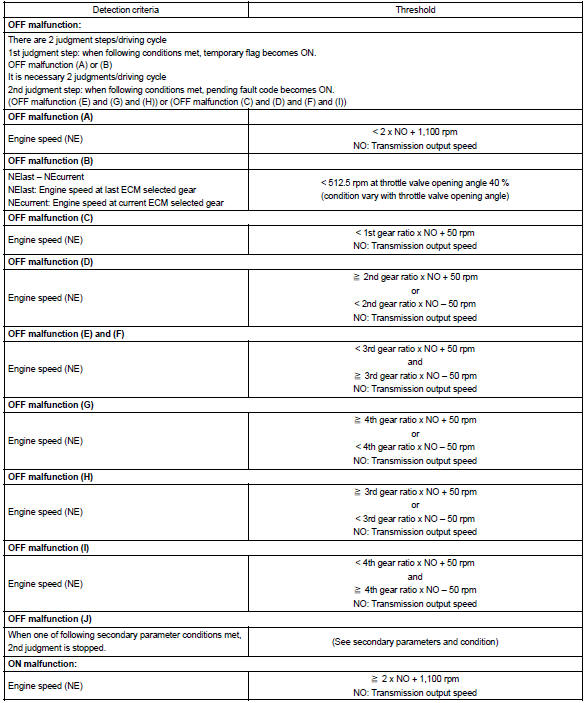

Typical malfunction thresholds

Other materials:

Fail–safe chart

If any of the following codes is recorded, the ecm enters the fail–safe mode.

Check for intermittent problems

Hand–held tester only:

by putting the vehicle’s ecm in the check mode, the 1 trip detection logic is

possible instead of the

2 trip detection logic, and the sensitivity to de ...

Wireless remote control/electronic key battery

Replace the battery with a

new one if it is depleted.

As the key may be damaged

if the following procedure is

not performed properly, it is

recommended that key battery

replacement be performed

by your Toyota

dealer.

■If the key battery is depleted

The following symptoms may occur:

The smart ke ...

Tire pressure warning system (if equipped)

Your vehicle is equipped with a tire pressure warning system that uses tire pressure

warning valves and transmitters to detect low tire inflation pressure before serious

problems arise.

◆ Installing tire pressure warning valves and transmitters

When replacing tires or wheels, tire press ...