Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Electronic controlled automatic transaxle / Diagnosis system

Toyota Corolla (E120): Diagnosis system

- Description

- when troubleshooting obd ii vehicles, the only difference from the usual troubleshooting procedure is that you need to connect an obd ii scan tool complying with sae j1987 or a hand–held tester to the vehicle, and read off various data output from the vehicle’s ecm.

- Obd ii regulations require that the vehicle’s on– board computer

illuminate the malfunction indicator lamp (mil) on the instrument panel when

the computer detects a malfunction in the computer itself or in the drive

system components which affect the vehicle emissions. In addition to the mil

illuminating when a malfunction is detected, the applicable dtcs prescribed

by sae j2012 are recorded in the ecm memory .

If the malfunction does not occur in 3 consecutive trips, the mil goes off but the dtcs remain in the ecm memory.

- To check the dtcs, connect the obd ii scan tool or hand–held tester to the dlc3 of the vehicle. The obd ii scan tool or hand–held tester also enables you to erase the dtcs and check freeze frame data and various forms of engine data (for instruction book).

- The dtcs include sae controlled codes and manufacturer controlled codes. Sae controlled codes must be set as prescribed by the sae, while manufacturer controlled codes can be set freely by a manufacturer within the prescribed limits (see the dtc chart on page 05–372).

- The diagnosis system operates in the normal mode

during the normal vehicle use, and also has a check

mode for technicians to simulate malfunction symptoms

and perform troubleshooting. Most dtcs use

2 trip detection logic(*) to prevent erroneous detection.

By switching the ecm to the check mode when troubleshooting, the technician can cause the mil to illuminate for a malfunction that is only detected once or momentarily. (Hand–held tester).

- *2 Trip detection logic: when a malfunction is first detected, the malfunction is temporarily stored in the ecm memory. If the same malfunction is detected again during the second test drive, this second detection causes the mil to illuminate.

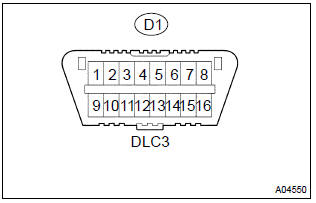

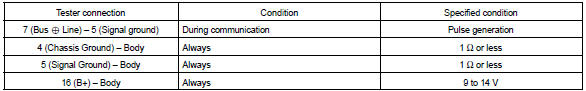

- Inspect the dlc3.

The vehicle’s ecm uses iso 9141–2 for communication.

The terminal arrangement of dlc3 complies with sae j1962 and matches the iso 9141–2 format.

Hint

: if your display shows unable to connect to vehicle when you have connected the cable of the obd ii scan tool or hand–held tester to the dlc3, turned the ignition switch to the on position and operated the scan tool, there is a problem on the vehicle side or tool side.

- If the communication is normal when the tool is connected to another vehicle, inspect the dlc3 on the original vehicle.

- If the communication is still impossible when the tool is connected to another vehicle, the problem is probably in the tool itself, so consult the service department listed in the tool’s instruction manual.

- measure the battery voltage.

Battery voltage: 11 to 14 v if voltage is below 11 v, recharge the battery before proceeding.

- check the mil.

- The mil comes on when the ignition switch is turned

to the on position and the engine is not running.

Hint

: if the mil does not light up, troubleshoot the combination meter.

- When the engine is started, the mil should go off.

If the lamp remains on, it means that the diagnosis system has detected a malfunction or abnormality in the system.

Other materials:

Turn signal lever

Operating instructions

1 Right turn

2 Lane change to the right (move the lever partway and release it)

The right hand signals will flash 3 times.

3 Lane change to the left (move the lever partway and release it)

The left hand signals will flash 3 times.

4 Left turn

■Turn signals can b ...

Problem symptoms table

If a normal code is displayed during the dtc check but the problem still

occurs, check the circuits for each

problem symptom in the order given in the table below and proceed to the

relevant troubleshooting page.

Notice:

when replacing skid control ecu, sensor or etc., Turn the ignition swi ...

Adjustment

Hint:

in the rh side, work in the same procedure as in the lh

side.

Since the centering bolt is used as a door side hinge bolt,

the door hinge cannot be adjusted with it on. Substitute

the bolt with washer for the centering bolt.

1. Inspect front door panel sub–assy lh

Che ...