Toyota Corolla (E120): Inspection procedure

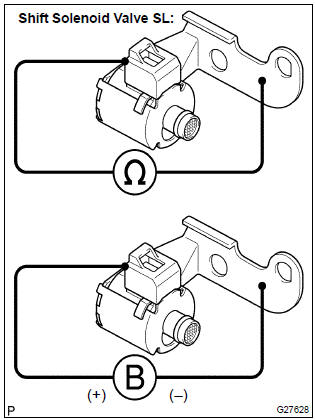

1 Inspect shift solenoid valve(sl)

- Remove the shift solenoid valve sl.

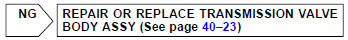

- measure the resistance according to the value(s) in the table below.

Standard:

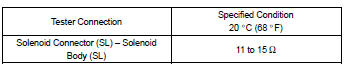

- Connect the positive (+) battery lead to the solenoid connector terminal, and the negative (–) battery lead to the solenoid body for checking the solenoid valve operation.

Standard: the solenoid valve makes an operating noise.

2 Inspect transmission valve body assy(see chapter 2 in the problem symptoms table)

3 Inspect torque converter clutch assy

Repair automatic transaxle assy

Other materials:

Check dlc3

The vehicle’s ecm uses the iso 9141–2 for communication

protocol. The terminal arrangement of the dlc3 complies

with sae j1962 and matches the iso 9141–2 format.

Hint:

if the display shows unable to connect to vehicle

when you have connected the cable of the obd ii scan tool or

the h ...

Using automatic mode

1 Press .

The dehumidification function begins to operate. Air outlets and fan speed are

automatically adjusted according to the temperature setting.

2 Adjust the temperature setting.

3 To stop the operation, press again.

■ If the system is operated manually in automatic mode

If the fa ...

Disabling the TRAC system

If the vehicle gets stuck in mud, dirt or snow, the TRAC system may reduce power

from the engine to the wheels. Pressing

to turn the system off may make it

easier for you to rock the vehicle in order to free it.

To turn the TRAC system off, quickly press and release

.

The “TRAC OFF” ind ...