Toyota Corolla (E120): Circuit description

Refer to dtc p0120

|

Dtc no. |

Dtc detection condition |

Trouble area |

| P0121 | The following condition is met 4 times. After the vehicle speed has exceeded 19 mph (30 km/h) once, the throttle position sensor output value is out of normal range when the throttle valve is closed at 0 km/h |

|

Monitor description

The throttle position sensor varies its resistance with the angle of the throttle valve. The ecm applies a regulated reference voltage to the throttle position sensor “+” terminal and calculates the angle of the throttle valve based on the voltage present at the throttle position sensor “signal” terminal.

When the throttle valve is near the fully closed position, the output voltage of the throttle position sensor is low. When it is near the fully open position, the output voltage is high.

The ecm checks the indicated angle of the throttle valve during “stop and go” conditions. If the indicated angle (or voltage) in the “closed throttle” position is out of the specified range, the ecm interprets this as a malfunction in the throttle position sensor and sets a dtc.

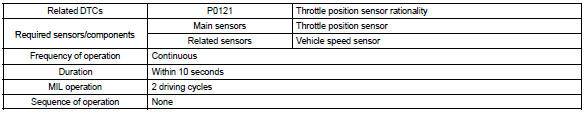

Monitor strategy

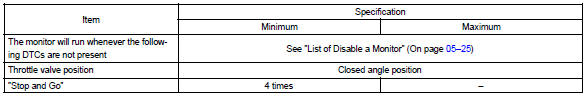

Typical enabling condition

”Stop and go” is defined as follows: ”stop” indicates a vehicle speed of 0 mph (0 km/h). ”Go” indicates a vehicle speed of 18.6 Mph (30 km/h).

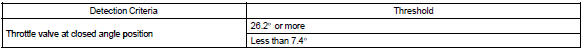

Typical malfunction thresholds

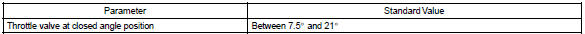

Component operating range

Other materials:

Driving assist systems

To help enhance driving safety and performance, the following systems operate

automatically in response to various driving situations. Be aware, however, that

these systems are supplementary and should not be relied upon too heavily when operating

the vehicle.

◆ ABS (Anti-lock Brake Sys ...

Inspection procedure

Hint:

read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is

useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the ...

Circuit description

The throttle pressure that is applied to the primary regulator

valve (which modulates the line pressure) causes the solenoid

valve slt, under electronic control, to precisely and minutely

modulate and generate the line pressure according the extent

of the accelerator pedal depressed or the o ...