Toyota Corolla (E120): Circuit description

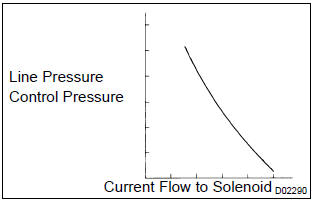

The throttle pressure that is applied to the primary regulator valve (which modulates the line pressure) causes the solenoid valve slt, under electronic control, to precisely and minutely modulate and generate the line pressure according the extent of the accelerator pedal depressed or the output of engine power.

This controls the line pressure and provides smooth shifting.

Upon receiving a signal of the throttle valve opening angle, the ecm controls the line pressure by sending a predetermined (*) duty ratio to the solenoid valve, modulating the line pressure and generating throttle pressure.

(*): Duty ratio the duty ratio is the ratio of the period of continuity in one cycle.

For example, if a is the period of continuity in one cycle, and b is the period of non–continuity, then duty ratio=a/(a+b) x 100 (%)

Monitor description

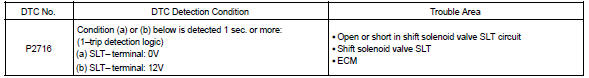

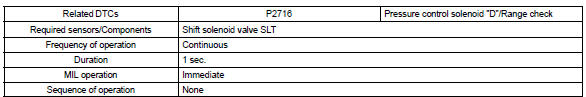

The linear solenoid valve (slt) controls the transmission line pressure for smooth transmission operation based on signals from the throttle position sensor and the vehicle speed sensor. The ecm adjusts the duty cycle of the slt solenoid valve to control hydraulic line pressure coming from the primary regulator valve.

Appropriate line pressure assures smooth shifting with varying engine outputs. When an open or short in the linear solenoid valve (slt) circuit is detected, the ecm interprets this as a fault. The ecm will turn on the mil.

Monitor strategy

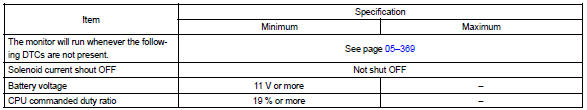

Typical enabling condition

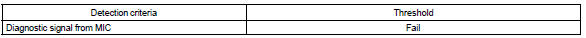

Typical malfunction thresholds

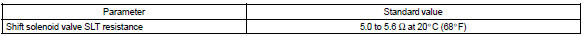

Component operating range

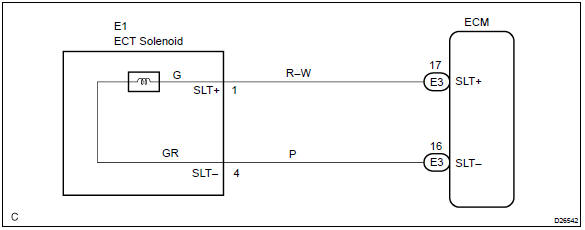

Wiring diagram

Other materials:

Transmission wire (atm)

Replacement

1. Remove transmission valve body assy

2. Remove transmission wire

Disconnect the transmission wire connector.

removal the bolt and transmission wire.

3. Install transmission wire

Coat a o–ring with atf.

install the transmission wire and bolt.

To ...

Malfunction in tachometer

Wiring diagram

Inspection procedure

Check output value of ecm.

Connect the hand–held tester to dlc3.

Turn the ignition switch to on and push the hand–held tester main switch

on.

Select the data list mode on the hand–held tester.

2 Inspect combinatio ...

Front no.2 Speaker assy

Replacement

Hint: components:

1. Remove front armrest assy lh

2. Remove power window regulator master switch assy (w/ power window)

3. Remove front armrest base panel upper lh (w/o power window)

4. Remove front door window regulator handle assy (w/o power window)

5. Remove front door lower ...