Toyota Corolla (E120): Inspection procedure

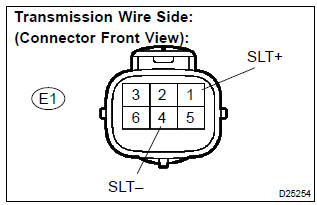

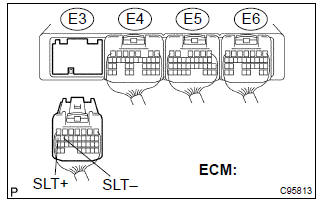

1 Inspect transmission wire(slt)

- Disconnect the transmission wire connector from the transaxle.

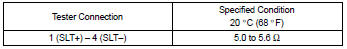

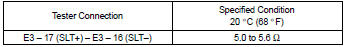

- measure the resistance according to the value(s) in the table below.

Standard:

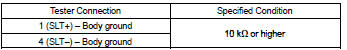

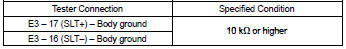

- Measure the resistance according to the value(s) in the

table below.

Standard (check for short):

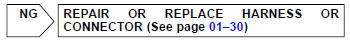

2 Check harness and connector(transmission wire – ecm)

- Connect the transmission wire connector to the transaxle.

- disconnect the ecm connector.

- measure the resistance according to the value(s) in the table below.

Standard:

- Measure the resistance according to the value(s) in the table below.

Standard (check for short):

Replace ecm

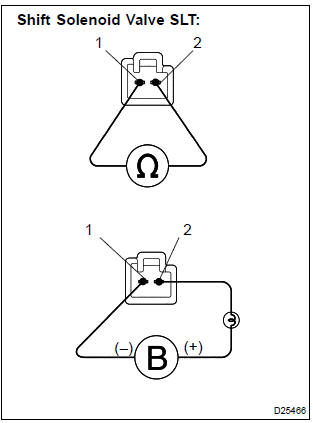

3 Inspect shift solenoid valve(slt)

- Remove the shift solenoid valve (slt).

- measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) battery lead with a 21 w bulb to the terminal 2 of the solenoid valve connector and the negative (–) battery lead to the terminal 1 of the solenoid valve connector for checking the solenoid valve operation.

Standard: the solenoid makes an operating noise.

Repair or replace transmission wire

Other materials:

Operating the touch screen

By touching the screen with your finger, you can control the multimedia system,

etc.

■ Drag*

Touch the screen with your finger, and move the screen to the desired position.

● Scrolling the lists

● Using scroll bar in lists

■ Flick*

Touch the screen with your finger an ...

Circuit description

Refer to dtc c0200/31, c0205/32, c1235/35, c1236/36

Hint:

Dtc no. C0210/33, c1238/38 is for the right rear speed sensor.

Dtc no. C0215/34, c1239/39 is for the left rear speed sensor.

Wiring diagram

...

On–vehicle inspection

1. Inspect speedometer

check the operation.

Using a speedometer tester, inspect the speedometer fro allowable

indication error and check

the operation of the odometer.

Reference:

Notice:

tire wear and tire over or under inflation will increase the indication error.

...