Toyota Corolla (E120): System description

The ecm uses the signals from the throttle position sensor, air–flow meter and crankshaft position sensor to monitor the engagement condition of the lock–up clutch.

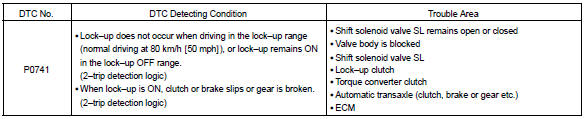

Then the ecm compares the engagement condition of the lock–up clutch with the lock–up schedule in the ecm memory to detect mechanical trouble of the shift solenoid valve sl, valve body and torque converter clutch or automatic transaxle (clutch, brake or gear etc.).

Monitor description

Based on the signals from the throttle position sensor, the airflow meter and the crankshaft position sensor, the ecm sends a signal to the shift solenoid valve sl to regulate the hydraulic pressure and provide smoother gearshifts. The shift–solenoid valve sl responds to commands from the ecm. The valve controls the lock–up relay valve to perform torque–converter lock–up and flexible lock–up functions.

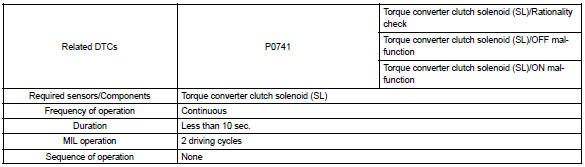

The ecm compares the engine rpm (ne) signal and the input speed calculated by output speed sensor (output speed) and gear ratio to detect torque converter lock–up. The ecm then compares the lock–up status against the lock–up schedule in the ecm memory. If the ecm does not detect lock–up at the appropriate time, it will conclude that there is a malfunction of shift solenoid sl. The ecm will illuminate the mil.

Monitor strategy

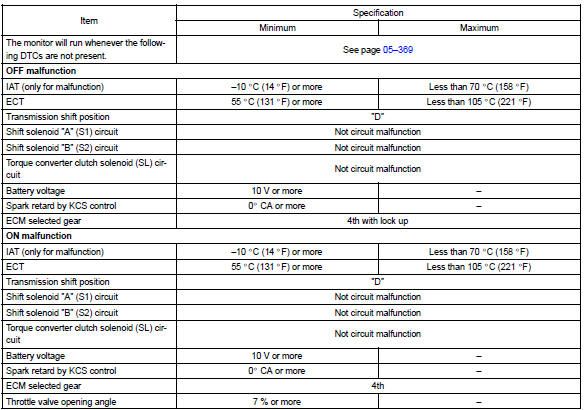

Typical enabling condition

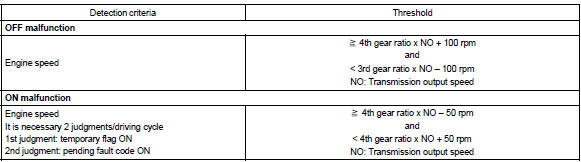

Typical malfunction thresholds

Other materials:

Skid control sensor

Replacement

Hint:

replace the rh side by the same procedure as the lh side.

1. Remove rear wheel

2. Remove rear brake drum sub–assy

3. Disconnect skid control sensor wire

Disconnect the skid control sensor wire connector from

the skid control sensor.

4. Remove rear axle hub & ...

Transmitter battery

Replacement

1. Replace transmitter battery

Notice:

special caution should be taken for handling each component as they are

precision electronic components.

Using a screwdriver, pry out the transmitter case.

Notice:

do not forcibly pry out the case.

Hint:

tape the screwdriver tip ...

Outside vehicle

General maintenance

Performing these maintenance checks on the vehicle in the owner’s

responsibility. The owner may

perform the maintenance or take the vehicle to a service center.

Check the parts of the vehicle described below on a daily basis. In most cases,

special tool are not

requir ...