Toyota Corolla (E120): Replacement

Hint

: installation is according to the reverse order of the removal.

1. Remove rear door weatherstrip rh

2. Remove rear door weatherstrip lh

3. Remove rear seat cushion assy (, 72–8)

4. Remove rear seat back assy (fixed type rear seat)

5. Remove separate type rear seat back assy (separated type rear seat)

6. Remove separate type rear seat back assy (separated type rear seat)

7. Remove room partition board rh (separated type rear seat)

8. Remove room partition board lh (separated type rear seat)

9. Remove roof side garnish inner rh

10. Remove roof side garnish inner lh

11. Remove package tray trim panel assy

12. Remove back window moulding outside upper

- Using a knife, cut off the moulding as shown in the illustration.

Notice

: do not damage the body with the knife.

- remove the remaining moulding.

Hint

: when removing, make a cut partly, pull and remove it by hand.

13. Remove back window glass

Hint

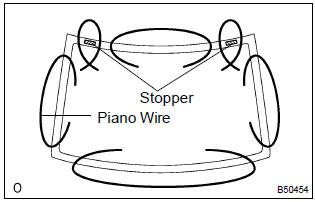

: depending on a vehicle type, either a 1–piece type or a 2–piece type of stopper is installed.

- Push a piano wire through between the body and glass from the interior.

- apply protective tape to the outer surface to keep the surface from being scratched.

- tie both wire ends to wooden blocks or similar objects.

Notice

: when separating the glass, take care not to damage the paint and interior/exterior ornaments.

To prevent the piano wire to be cut, do not cross it.

- cut the adhesive by pulling the piano wire around it.

- using a suction rubber, remove the glass.

Notice

: leave as much adhesive on the body as possible when cutting off the glass.

14. Clean back window glass

- using a scraper, remove the damaged stoppers, dam and adhesive sticking to the glass.

- clean the outer circumference of the glass with white gasoline.

Notice

:

- do not touch the glass after cleaning it.

- Be careful not to damage the body.

15. Install back window glass stopper no.1

- install 2 new back window glass stoppers no.1 To the body.

16. Install back windw glass stopper no.2

- Coat the installation part of the stopper with primer g.

Notice

:

- dry the primer coating for 3 minutes or more.

- Do not apply too much primer.

- install 2 new back window glass stoppers no.2 Onto the

glass as shown in the illustration.

A: 40.0 Mm (1.575 In.)

B: 11.3 Mm (0.445 In.)

17. Install back window glass adhesive dam

- coat the installation part of the window glass adhesive dam with primer g.

Notice

:

- dry the primer coating for 3 minutes or more.

- Do not apply too much primer.

- Install a new window glass adhesive dam as shown in the illustration.

A: 25.0 Mm (0.984 In.)

B: 9.0 Mm (0.354 In.)

18. Install back window glass

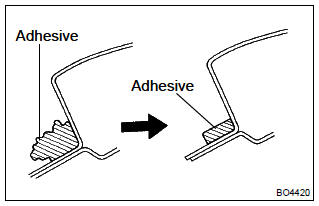

- Clean and shape the contact surface of the vehicle’s body

- using a knife, cut away any rough areas of the body.

Hint

: leave as much adhesive on the body as possible.

- Clean the cut surface of the adhesive with a piece of shop rag saturated in cleaner.

- position the glass.

- Using a suction rubber, place the glass in the correct position.

- ) Check that all the contacting parts of the glass rim are perfectly even.

- Place reference marks between the glass and body.

Notice

: check that the stoppers are attached to the body correctly.

Hint

: when reusing the glass, check and correct the reference mark’s positions.

- Remove the glass.

- coat the contact surface of the body panel with primer m.

- Using a brush, coat the exposed part of the contact surface on the vehicle side with primer m.

Notice

:

- dry the primer coating for 3 minutes or more.

- Do not apply too much primer.

- coat the contact surface of the glass with primer g.

- Using a brush or sponge, coat the edge of the glass and the contact surface with primer g.

Notice

:

- dry the primer coating for 3 minutes or more.

- Do not apply too much primer.

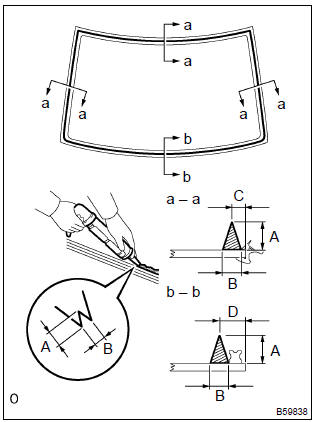

- apply adhesive.

- Cut off the tip of the cartridge nozzle as shown in the

illustration.

Part no. 08850–00801 Or equivalent

Hint

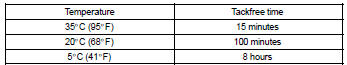

: after cutting off the tip, use all adhesive within the time described in the table below.

- Load the sealer gun with the cartridge.

- Coat the glass with adhesive as shown in the illustration.

A: 12.5 Mm (0.492 In.) Or more b: 8 mm (0.32 In.) Or more c: 6.5 Mm (0.256 In.)

D: 13 mm (0.51 In.)

- install the glass.

- Using a suction rubber, position the glass so that the reference marks are aligned, and press it in gently along the rim.

Notice

:

- dry the primer coating for 3 minutes or more.

- Check that the stoppers are attached to the body correctly.

- Check the clearance between the body and glass.

- Lightly press the glass front surface for close contact.

- Using a scraper, remove any excess or protruding adhesive.

Hint

: apply adhesive on the glass rim.

19. Install back window moulding outside upper

- install a new back window moulding to the back window glass before the adhesive has hardened.

- hold the back window glass in place securely with protective tape or equivalent until the adhesive has completely hardened.

- using a scraper, remove any excess or protruding adhesive before the adhesive has hardened.

Notice

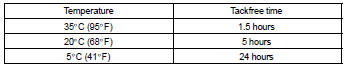

: take care not to drive the vehicle during the time described in the table below.

20. Inspect for leak and repair

- conduct a leak test after the adhesive has completely hardened.

- Seal any leak with sealant.

21. Install rear seat back assy (fixed type rear seat)

22. Install separate type rear seat back assy (separated type rear seat)

23. Install separate type rear seat back assy (separated type rear seat)

Other materials:

Eco drive mode (if equipped)

Press the switch.

Suitable for enhancing the fuel economy, because the torque corresponding to

the accelerator pedal depression amount can be generated more smoothly than it is

in normal conditions and the operation of the air conditioning system (heating/cooling)

will be minimized.

Press th ...

Checking and replacing fuses

If any of the electrical components do not operate, a fuse may have blown.

If this happens, check and replace the fuses as necessary.

1 Turn the engine switch off.

2 Open the fuse box cover.

► Engine compartment

Push the tab in and lift the lid off.

► Under the driver’s side i ...