Toyota Corolla (E120): Replacement

1. Disconnect battery negative terminal

2. Remove engine under cover rh

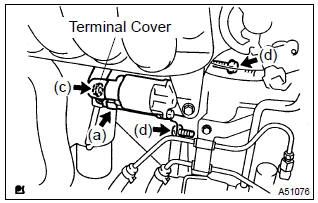

3. Remove starter assy

- Disconnect the starter connector.

- open the terminal cover.

- remove the nut, then disconnect the starter wire.

- remove the 2 bolts, then remove the starter.

4. Install starter assy

Torque:

37 nvm (378 Kgf·cm, 27 ft·lbf) for bolt

9.8 Nvm (100 Kgf·cm, 7 ft·lbf) for nut

5. Install engine under cover rh

6. Connect battery negative terminal

torque: 5.4 Nvm (55 Kgf·cm, 48 in.Vlbf)

Other materials:

Circuit description

While driving uphill with cruise control activated, in order to minimize gear

shifting and provide smooth cruising

overdrive may be prohibited temporarily under some conditions.

The cruise control ecu sends o/d cut signals to the ecm as necessary and the ecm

cancels overdrive

shifting until ...

Inspection procedure

1 Check wire harness(airbag sensor assy center – front seat inner

belt assy lh)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the front seat inner belt assy ( ...

Front axle lh hub bolt

Replacement

Hint: components:

1. Remove front wheel

2. Separate front disc brake caliper assy lh

3. Remove front disc

4. Remove front axle lh hub bolt

Using sst and a hammer handle or an equivalent, remove

the lh hub bolt.

Sst 09628–10011

5. Install front axle lh hub bolt

...