Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Evaporative emission control

system pressure sensor / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

:

- if different dtcs related to different systems that have terminal e2 as the ground terminal are output simultaneously, terminal e2 may be open.

- If dtc p0441 (purge flow), p0446 (vsv for ccv), p0451, p0452 or p0453 (evaporative pressure sensor) is output with dtc p0442 or p0456, troubleshoot dtc p0441, p0446, p0451, p0452 or p0453 first. If no malfunction is detected, troubleshoot dtc p0442 or p0456 next.

- Read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

- If the engine run time in the freeze frame data is less than 200 seconds, carefully check the vapor pressure sensor.

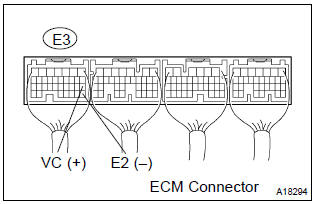

1 Inspect ecm(vc voltage)

- Turn the ignition switch on.

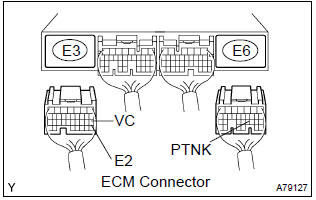

- measure the voltage between the terminals of the e3 ecm connector.

Standard:

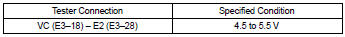

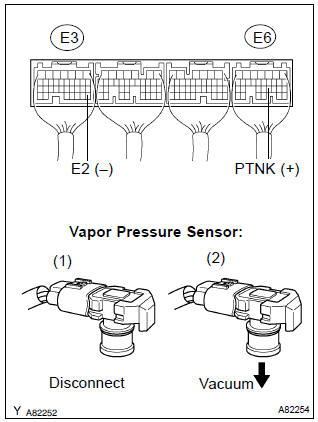

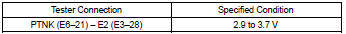

2 Inspect ecm(ptnk voltage)

- Turn the ignition switch on.

- measure the voltage between the terminals of the e3 and e6 ecm connectors.

- Disconnect the vacuum hose from the vapor pressure sensor.

Standard (1):

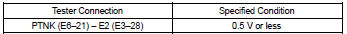

- Using the mityvac (hand–held vacuum pump), apply a vacuum of 4.0 Kpa (30 mmhg, 1.18 In.Hg) to the vapor pressure sensor.

Notice

: the vacuum applied to the vapor pressure sensor must be less than 66.7 Kpa (500 mmhg, 19.7 In.Hg).

Standard (2):

- Reconnect the vacuum hose.

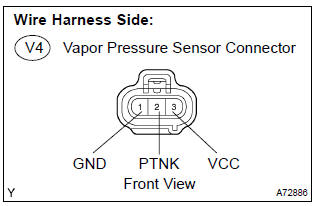

3 Check harness and connector(vapor pressure sensor – ecm)

- Disconnect the v4 vapor pressure sensor connector.

- disconnect the e3 and e6 ecm connectors.

- check the resistance between the wire harness side connectors.

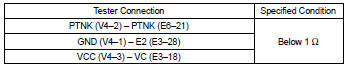

Standard (check for open):

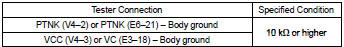

Standard (check for short):

- Reconnect the ecm connectors.

- reconnect the vapor pressure sensor connector.

Replace vapor pressure sensor assy

Other materials:

Bluetooth®

■When using the Bluetooth® audio system

●In the following situations, the system may not function.

• The portable player does not support Bluetooth®

• The cellular phone is located outside the service area

• The Bluetooth® device is switched off

• The Bluetooth® device h ...

Replacement

Hint: components:

1. Remove front wheel

2. Remove front axle hub lh nut

sst 09930–00010

3. Separate front stabilizer link assy lh

4. Separate speed sensor front lh (w/ abs)

5. Separate front disc brake caliper assy lh

Remove the 2 bolts, separate the brake caliper assy ...

Front passenger occupant classification

system

Your vehicle is equipped with a front passenger occupant

classification system. This system detects the conditions of

the front passenger seat and activates or deactivates the front

passenger airbag and seat cushion airbag in the front passenger

side.

System components

SRS warning light

Front pa ...