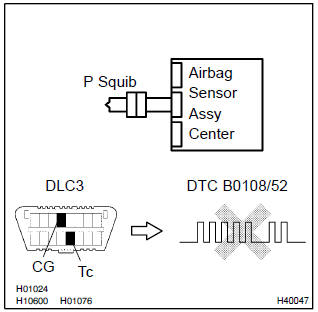

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p squib circuit (to b+) / Inspection procedure

Toyota Corolla (E120): Inspection procedure

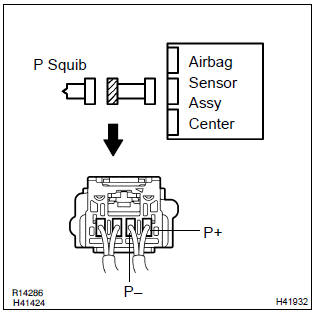

1 Check p squib circuit(airbag sensor assy center – instrument panel passenger airbag assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on.

- for the connector (on the instrument panel passenger airbag

assy side) between the airbag sensor assy center

and the instrument panel passenger airbag assy, measure

the voltage between p+ and body ground.

Ok: voltage: below 1 v

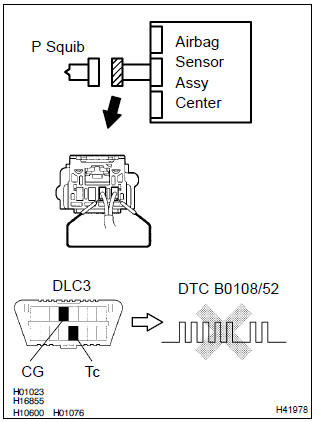

2 Check air bag sensor assy center

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the connector to the airbag sensor assy center.

- using a service wire, connect p+ and p– of the connector (on the instrument panel passenger airbag assy side) between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0108/52 is not output.

Hint

: codes other than code b0108/52 may be output at this time, but they are not relevant to this check.

3 Check p squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the instrument panel passenger airbag assy connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0108/52 is not output.

Hint

: codes other than code b0108/52 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Registering a Bluetooth® phone for the first time

To use the hands-free system, it is necessary to register a Bluetooth® phone

with the system.

Once the phone has been registered, it is possible to use the hands-free system.

For details about registering a Bluetooth® device

1 Turn the Bluetooth® connection setting of your cellular phone on. ...

Inspection procedure

1 Check p squib circuit(airbag sensor assy center – instrument

panel passenger airbag assy)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the instrument panel ...

Listening to a USB memory device

Connecting a USB memory device enables you to enjoy music from the vehicle

speakers.

Touch “USB” on the audio source selection screen.

Connecting a USB memory device

Audio control screen

Pressing the “AUDIO” button displays the audio control screen from any screens

of the selected so ...