Toyota Corolla (E120) 2002–2008 Repair Manual / Front suspension / Stabilizer bar front

Toyota Corolla (E120): Stabilizer bar front

Replacement

Hint

: components:

1. Remove front wheel

2. Remove front stabilizer link assy lh

- Remove the 2 nuts and stabilizer bar link.

Hint

: if the ball joint turns together with the nut, use a hexagon wrench (6 mm) to hold the stud. 3. Remove front stabilizer link assy rh

Hint

: remove the rh side by the same procedure as the lh side.

4. Inspect front stabilizer link assy

- As shown in the illustration, flip the ball joint stud back and forth 5 times, before installing the nut.

- using a torque wrench, turn the nut continuously at a rate

of 2 – 4 seconds per 1 turn and take the torque reading

on the 5th turn.

Turning torque: 0.05 – 1.96 Nvm (0.5 – 20 Kgf·cm, 0.4 – 17 In.Vlbf)

5. Separate front suspension arm sub–assy lower no.1 Lh

6. Separate front suspension arm sub–assy lower no.1 Rh

Hint

: remove the rh side by the same procedure as the lh side.

7. Separate rack & pinion power steering gear assy

8. Suspend engine assy

at:

mt:

9. Separate front suspension crossmember sub–assy

10. Remove stabilizer bar front

- remove the 4 bolts,front stabilizer bracket no.1 Lh, front stabilizer bracket no.1 Rh, 2 front stabilizer bar bushes no.1 And stabilizer bar front from the front suspension crossmember sub–assy.

- remove the 2 front stabilizer bar bushes no.1 From the stabilizer bar front.

11. Install stabilizer bar front

- Install 2 front stabilizer bar bushes no.1, Front stabilizer bracket no.1 Lh and front stabilizer bracket no.1 Rh to the stabilizer bar front.

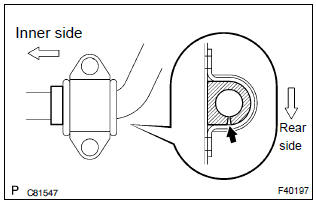

Hint

: install the bushing to the inner side of the bushing stopper on the stabilizer bar.

- Install the stabilizer bar front and 4 bolts to the front suspension

crossmember sub–assy.

Torque: 19 nvm (194 Kgf·cm, 14 ft·lbf)

12. Install front suspension crossmember sub–assy sst 09670–00010

13. Install rack & pinion power steering gear assy

14. Install front suspension arm sub–assy lower no.1 Lh

15. Install front suspension arm sub–assy lower no.1 Rh

H

int

: install the rh side by the same procedures as the lh side.

16. Install front stabilizer link assy lh

- Install the stabilizer bar link with the 2 nuts.

Torque: 74 nvm (755 Kgf·cm, 55 ft·lbf)

H

int

: if the ball joint turns together with the nut, use a hexagon wrench (6 mm) to hold the stud.

17. Install front stabilizer link assy lh

Hint

: install the rh side by the same procedure as the lh side.

18. Install front wheel

torque: 103 nvm (1,050 Kgf·cm, 76 ft·lbf)

19. Inspect and adjust front wheel alignment

Other materials:

Message Settings

1 Display the “Phone/Message Settings” screen. 2 Select “Messaging Settings”.

3 Select the desired item to be set.

1 Set automatic message transfer on/off.

2 Set automatic message readout on/off.

3 Set the SMS/MMS notification popup on/off.

4 Set the e-mail notification popup on/off.

5 ...

Safety information for children

Observe the following precautions when children are in the vehicle.

Use a child restraint system appropriate for the child, until the child becomes

large enough to properly wear the vehicle’s seat belt.

● It is recommended that children sit in the rear seats to avoid accidental contact

...

Inspection

1. Fuel injector assy

Inspect injector resistance.

Using an ohmmeter,measure the resistance between

the terminals.

Resistance: 13.4 – 14.2 Ω at 20 c (68 f)

Inspect injector inspection

Caution:

keep injector clear of sparks during the test.

Purch ...