Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in squib (2nd step) circuit (to

b+) / Inspection procedure

Toyota Corolla (E120): Inspection procedure

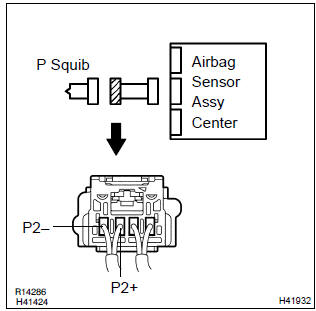

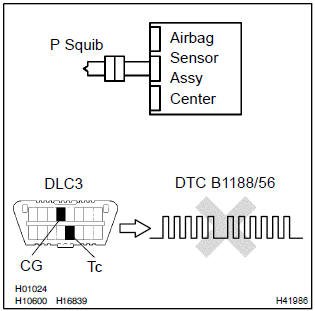

1 Check p squib circuit(airbag sensor assy center – instrument panel passenger airbag assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connector between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on.

- for the connector (on the instrument panel passenger airbag assy side) between the airbag sensor assy center and the instrument panel passenger airbag assy, measure the voltage between p2+ and body ground.

Ok: voltage: below 1 v

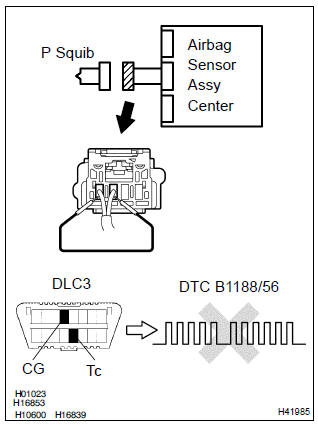

2 Check air bag sensor assy center

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the connector to the airbag sensor assy center.

- using a service wire, connect p2+ and p2– of the connector (on the instrument panel passenger airbag assy side) between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1188/56 is not output.

Hint

: codes other than code b1188/56 may be output at this time, but they are not relevant to this check.

3 Check p squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the instrument panel passenger airbag assy connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1188/56 is not output.

Hint

: codes other than code b1188/56 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Key information

Keys

The following keys are provided with the vehicle.

► Vehicles without a smart key system

(type A)

1 Keys

2 Key number plate

► Vehicles without a smart key system (type

B)

1 Keys

Operating the wireless remote control function

2 Key number plate

► Vehicles ...

Amplifier antenna assy

Replacement

Hint: components:

Remove roof headlining assy

Notice:

do not bend the roof headlining assy.

Hint:

refer to the procedure from ”remove roof headlining assy” of roof

headlining assy.

Remove the related parts as long as the amplifier antenna assy can be

removed. ...

Unlocking and locking the doors from the outside

◆ Smart key system (if equipped)

Carry the electronic key to enable this function.

1 Grip the driver’s door handle to unlock the door. Grip the passenger’s door

handle to unlock all the doors.* Make sure to touch the sensor on the back of the

handle.

The doors cannot be unlocked for ...