Toyota Corolla (E120): Inspection procedure

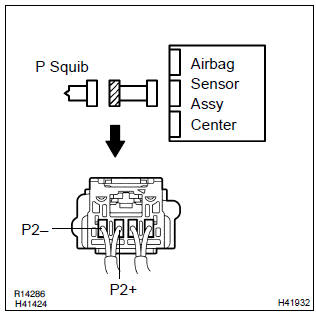

1 Check p squib circuit(airbag sensor assy center – instrument panel passenger airbag assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connector between the airbag sensor assy center and the instrument panel passenger airbag assy.

- for the connector (on the instrument panel passenger airbag

assy side) between the airbag sensor assy center

and the instrument panel passenger airbag assy, measure

the resistance between p2+ and body ground.

Ok: resistance: 1 mΩ or higher

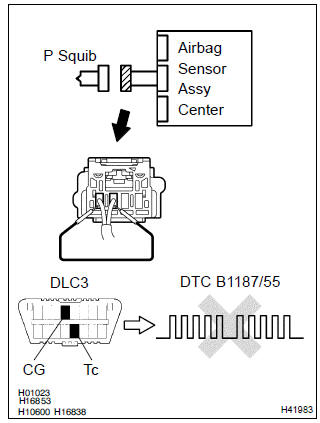

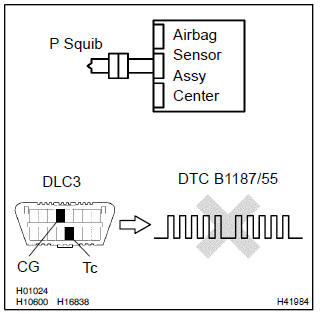

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- using a service wire, connect p2+ and p2– of the connector (on the instrument panel passenger airbag assy side) between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1187/55 is not output.

Hint

: codes other than code b1187/55 may be output at this time, but they are not relevant to this check.

3 Check p squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the instrument panel passenger airbag assy connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1187/55 is not output.

Hint

: codes other than code b1187/55 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

AUX port/USB port

Connect an iPod, USB memory device or portable audio player to the AUX port/USB

port as indicated below. Press to select

“iPod”, “USB” or “AUX”.

Connecting using the AUX port/USB port

■ iPod

Open the cover and connect an iPod using an iPod cable.

Turn on the power of the i ...

Inspection

1. Inspect outer mirror switch assy

Inspect the mirror switch continuity.

Left side for left/right adjustment switch:

inspect the mirror switch continuity

Standard (left side):

If the result is not as specified, replace the switch assembly.

Right side for left/r ...

Inspection procedure

Hint:

read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is

useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the ...