Toyota Corolla (E120): Inspection procedure

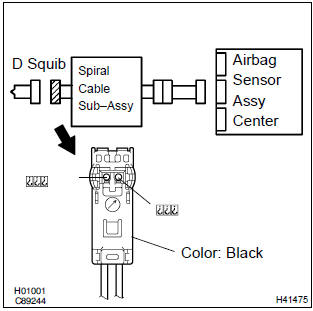

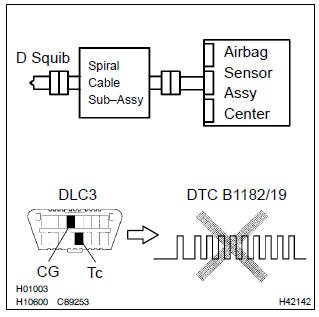

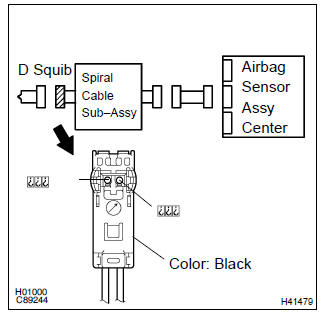

1 Check d squib circuit(airbag sensor assy center – horn button assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connector between the airbag sensor assy center and the horn button assy.

- for the black connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the resistance between d2+ and

body ground.

Ok: resistance: 1 mw or higher

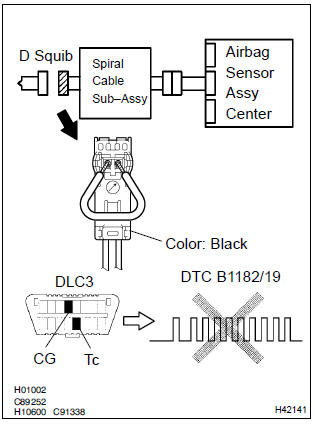

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- using a service wire, connect d2+ and d2– of the black connector (on the spiral cable sub–assy side) between the horn button assy and the spiral cable sub–assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait t least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1182/19 is not output.

Hint

: codes other than code b1182/19 may be output at this time, but they are not relevant to this check.

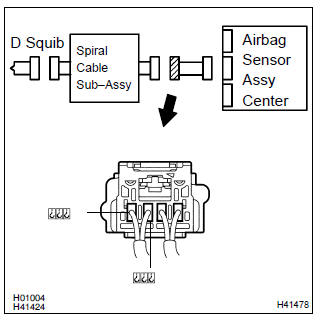

3 Check d squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the horn button assy connectors.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1182/19 is not output.

Hint

: codes other than code b1182/19 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

5 Check instrument panel wire(airbag sensor assy center – spiral cable sub–assy)

- Disconnect the connector of the instrument panel wire.

- for the connector (on the spiral cable sub–assy side) between

the airbag sensor assy center and the spiral cable

sub–assy, measure the resistance between d2+ and

body ground.

Ok: resistance: 1 mΩ or higher

6 Check spiral cable sub–assy

- For the black connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the resistance between d2+ and

body ground.

Ok: resistance: 1 mΩ or higher

7 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Precaution

Caution:

replace the faulty parts of the seat belt systems (outer belt, inner belt,

bolts, nuts, adjustable shoulder

anchor, tether anchor hardware, sill–bar, etc.).

Seat belt systems not in use at the time of a collision should also be inspected

and replaced if found

to be damaged or wo ...

Installing tire pressure

warning valves and transmitters

(vehicles with a

tire pressure warning system)

When replacing tires or wheels,

tire pressure warning valves and transmitters must also be

installed.

When new tire pressure warning

valves and transmitters are

installed, new ID codes must be

registered in the tire pressure

warning computer and the tire

pressure warning system must

be initialized. ...

Circuit description

The shift solenoid valve sl is turned ”on” and ”off” by signals from the ecm

in order to control the hydraulic

pressure operation, the lock–up relay valve, which then the controls operation

of the lock–up clutch.

Fail safe function:

if the ecm detects a malfunction, it turns the ...