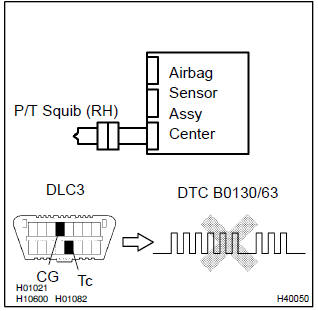

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p/t squib (rh) circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

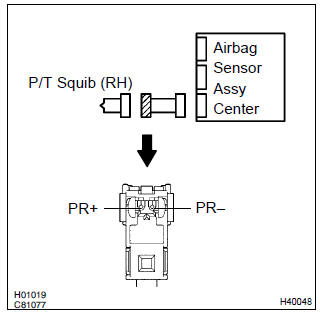

1 Check p/t squib(rh) circuit(airbaga sensor assy center – front seat outer belt assy rh)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor

assy center and the seat belt pretensioner (rh).

Hint

: make sure that the connector is not damaged (the lock button is not disengaged, or the claw of the lock is not deformed or damaged). If the damage is found, replace the wire harness.

- release the airbag activation prevention mechanism of the connector (on the airbag sensor assy center side) between the airbag sensor assy center and the seat belt pretensioner (rh) .

- for the connector (on the seat belt pretensioner side) between

the airbag sensor assy center and the seat belt pretensioner

(rh), measure the resistance between pr+

and pr–.

Ok: resistance: 1 mΩ or higher

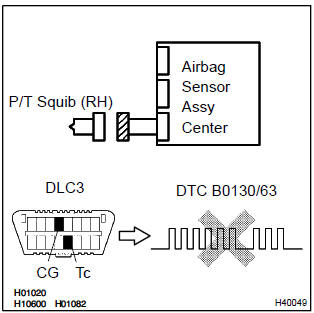

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0130/63 is not output.

Hint

: codes other than code b0130/63 may be output at this time, but they are not relevant to this check.

3 Check p/t squib (rh)

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the seat belt pretensioner (rh) connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0130/63 is not output.

Hint

: codes other than code b0130/63 may be output at this time, but they are not relevant to this check.

Use simulation method to check

Other materials:

Tire pressure warning system (if equipped)

Your vehicle is equipped with a tire pressure warning system that uses tire pressure

warning valves and transmitters to detect low tire inflation pressure before serious

problems arise.

◆ Installing tire pressure warning valves and transmitters

When replacing tires or wheels, tire press ...

Drive shaft / propeller shaft

Preparation

Sst

Recomended tools

Equipment

Lubricant

...

Terminals of ecu

1. Inspect integration relay

Disconnect the connector and check the continuity of each terminal of

the disconnected connector.

Standard :

If the result is not as specified, the vehicle’s side may malfunction.

Reconnect the connector and check each terminal.

Standard:

If ...