Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Knock sensor 1 circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

1 Read output dtc

- Clear the dtc.

- warm up the engine.

- run the engine at 3,000 rpm for 10 seconds or more.

- connect the hand–held tester or the obd ii scan tool to the dlc3.

- turn the ignition switch on and push the hand–held tester or the obd ii scan tool main switch on.

- select the item ”diagnosis / enhanced obd ii / dtc info / current codes”.

- read the dtcs.

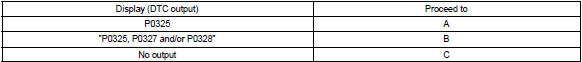

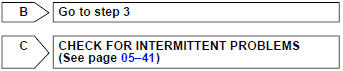

Result :

2 Inspect knock sensor

- Check the knock sensor installation.

Torque: 20 nvm (204 kgf·cm, 15 ftvlbf)

3 Check harness and connector(ecm – knock sensor)

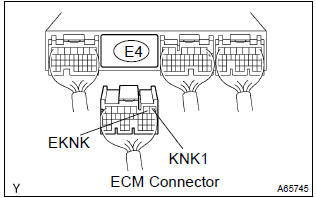

- Disconnect the e4 ecm connector.

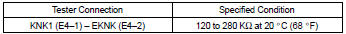

- measure the resistance between terminals of the e4 ecm connector.

Standard:

- Reconnect the ecm connector.

4 Inspect ecm(knk1 voltage)

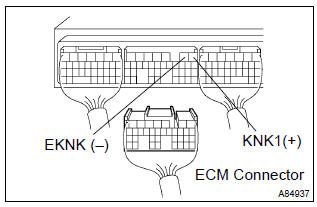

- Disconnect the e4 ecm connector.

- turn the ignition switch on.

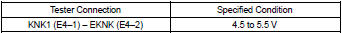

- measure the voltage between terminals of the e4 ecm terminals.

Standard:

- Reconnect the ecm connector.

Check for intermittent problems

Notice

: fault may be intermittent. Check harness and connectors carefully.

5 Inspect knock sensor

- Remove the k1 knock sensor.

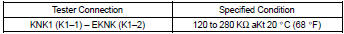

- measure the resistance between the terminals.

Standard:

- Reinstall the knock sensor.

Repair or replace harness or connector

Other materials:

Inspection procedure

1 Check source voltage

Measure the voltage of the battery.

Ok:

voltage: 10 – 14 v

2 Check air bag sensor assy center

Disconnect the negative (–) terminal cable from the battery, and wait at

least for 90 seconds.

disconnect the connectors from the airbag sensor assy ...

Indicators

The indicators inform the driver of the operating state of the vehicle’s various

systems.

*1: Vehicles without a smart key system:

These lights turn on when the engine switch is turned to the “ON” position to indicate

that a system check is being performed. They will turn off after the ...

Using the interior lights

Interior lights list

1 Front interior light/personal lights

2 Rear interior light

3 Engine switch light (vehicles with a smart key system)

Front interior light/personal lights

■ Front interior light

► Type A

► Type B

1 Off

2 Door position

3 On

■ Personal li ...