Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Readiness monitor drive pattern / Evap monitor (vacuum pressure monitor) (continued)

Toyota Corolla (E120): Evap monitor (vacuum pressure monitor) (continued)

- Preconditions

The monitor will not run unless:

- mil is off.

- Fuel level is approximately 1/2 to 3/4.

- Altitude is 7800 feet (2400 m) or less.*

- Engine coolant temperature (ect) is between 40°f and 95°f (4.4 °C and 35 °C).

- Intake air temperature (iat) is between 40°f and 95 °f (4.4 °C and 35 °C).*

- Cold soak procedure has been completed.

- Before starting the engine, the difference between ect and iat must be less than 13°f (7 °C).

Hint

:

examples:

- scenario 1

ect = 75°f (24 °C)

iat = 60°f (16 °C)

difference between ect and iat is 15°f (8 °C).The monitor will not run because difference between ect and iat is greater than 13°f (7 °C).

- Scenario 2

ect = 70°f (21 °C)

iat = 68°f (20 °C)

difference between ect and iat is 2°f (1 °C).The monitor will run because difference between ect and iat is less than 13°f (7 °C).

Notice

: * note for 2002 and later my vehicles: the readiness test can be completed in cold ambient conditions (less than 40°f / 4.4 °C) and/or at high altitudes (more than 7800 feet / 2400 m) if the drive pattern is repeated a second time after cycling the ignition off.

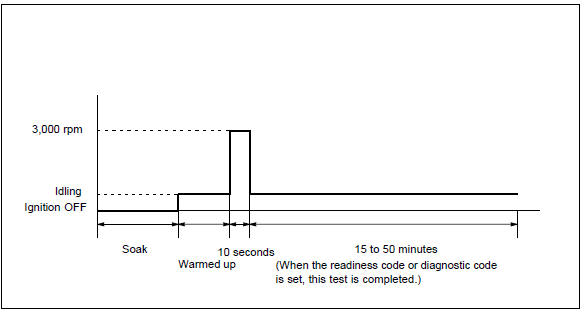

- Drive pattern

- connect the obd ii scan tool to dlc3 to check monitor status and preconditions.

- Release pressure in the fuel tank by removing and then reinstalling the fuel tank cap.

- Start the engine and allow it to idle until ect becomes 167°f (75 °C) or greater.

- Run the engine at 3,000 rpm for about 10 seconds.

- Allow the engine to idle with the a/c on (to create slight load) for 15 to 50 minutes.

Notice

: if the vehicle is not equipped with a/c put a slight load on the engine by doing the following :

- securely set the parking brake.

- Block the drive wheels with wheel chocks.

- Allow the vehicle to idle in drive for 15 to 50 minutes.

Other materials:

Rear speaker assy

Replacement

Hint: components:

1. Remove rear door opening trim rh

2. Remove rear door opening trim lh

3. Remove bench type rear seat cushion assy( or 72–8)

4. Remove rear seat back assy (fixed type rear seat)

5. Remove rear seat back assy (separated type rear seat)

6. Remove rear seat side ...

Dtc check/clear

Notice:

if there is no dtc in the normal mode, check the pending

fault code using the continuous test results

function (mode 7 for sae j1979) on the obd ii scan

tool or the hand–held tester.

Hand–held tester only:

when the diagnosis system is switched from the normal

mode to the ...

Air conditioning controls

■ Adjusting the temperature setting

To adjust the temperature setting, turn

clockwise to increase the temperature

and turn counterclockwise to decrease

the temperature.

■ Fan speed setting

Press “>” on to increase the fan

speed.

Press “<” on to decrease the ...