Toyota Corolla (E170): Engine coolant

The coolant level is satisfactory if it is between the “F” and “L” lines on the reservoir when the engine is cold.

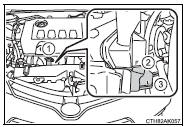

1 Reservoir cap

2 “F” line

3 “L” line

If the level is on or below the “L” line, add coolant up to the “F” line.

■Coolant selection

Only use “Toyota Super Long Life Coolant” or a similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate coolant with long-life hybrid organic acid technology.

For the U.S.A.: “Toyota Super Long Life Coolant” is a mixture of 50% coolant and 50% deionized water. (Minimum temperature: -31°F [-35°C]) For Canada: “Toyota Super Long Life Coolant” is a mixture of 55% coolant and 45% deionized water. (Minimum temperature: -44°F [-42°C])

For more details about engine coolant, contact your Toyota dealer.

■If the coolant level drops within a short time of replenishing

Visually check the radiator, hoses, engine coolant reservoir caps, drain cock and water pump.

If you cannot find a leak, have your Toyota dealer test the cap and check for leaks in the cooling system.

CAUTION

■When the engine is hot

Do not remove the engine coolant reservoir cap or the radiator cap.

The cooling system may be under pressure and may spray hot coolant if the cap is removed, causing serious injuries, such as burns.

NOTICE

■When adding coolant

Coolant is neither plain water nor straight antifreeze. The correct mixture of water and antifreeze must be used to provide proper lubrication, corrosion protection and cooling. Be sure to read the antifreeze or coolant label.

■If you spill coolant

Be sure to wash it off with water to prevent it from damaging parts or paint.

Other materials:

Toyota Safety Sense 3.0 software

update

It is necessary to enter a

connected services contract,

provided by Toyota, to

use these functions. For

details, contact your Toyota

dealer.

WARNING

■For safe use

When the Toyota Safety Sense

3.0 software is updated, the operating

methods of functions may

change. Using this system without

knowing ...

Symptom simulation

Hint:

the most difficult case in troubleshooting is when no symptoms occurs. In such

cases, a thorough customer

problem analysis must be carried out. Then the same or similar conditions and

environment in which the

problem occurred in the customer’s vehicle should be simulated. No matter ho ...

Manual air conditioning system

Air conditioning controls

The display and button positions will differ depending on the type of

the system.

Fan speed control switch

Temperature control switch

"MAX A/C" switch

"A/C" switch

Outside air mode switch

Recirculated air mode switch

Airflow mode control switch

Rear window defogge ...