Toyota Corolla (E120): Basic inspection

When the malfunction is not confirmed in the dtc check, troubleshooting should be carried out in all the possible circuits considered as causes of the problem. In many cases, by carrying out the basic engine check shown in the following flowchart, the location causing the problem can be found quickly and efficiently. Therefore, using this check is essential in the engine troubleshooting.

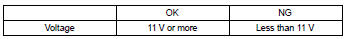

1 Check battery voltage

Notice

: carry out this check with the engine stopped and ignition switch off.

Ng charge or replace battery

2 Check if engine will crank

Ng proceed to problem symptoms table on page

3 Check if engine starts

Ng go to step 7

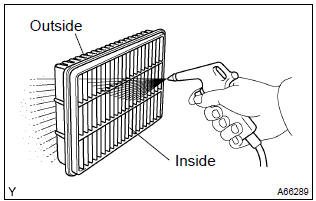

4 Check air filter

- Visually check that the air filter is not excessively dirty or oily.

Notice

: if necessary, clean the filter with compressed air. First blow from the inside thoroughly, then blow from the outside of the filter.

Ng clean or replace

5 Check idle speed

Ng proceed to problem symptoms table on page

6 Check ignition timing

Ng proceed to page 14–1 and continue to troubleshoot

Proceed to problem symptoms table on page

7 Check fuel pressure

Ng proceed to page 11–1 and continue to troubleshoot

8 Check for spark

Ng proceed to page 18–1 and continue to troubleshoot

Proceed to problem symptoms table on page

Other materials:

Pre–check

1. Diagnosis check

Starting diagnosis mode (service check mode)

turn off the audio system and turn the ig switch to

acc. While pressing the preset switches ”1” and ”6”

at the same time, press ”cd” 3 times.

Reference:

beep sound is given 3 times and the sys ...

Inspection procedure

Hint:

read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is

useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the ...

Overhaul

Hint: components:

1. Remove rear wheel

2. Remove spare wheel cover assy

3. Remove rear floor finish plate

4. Remove luggage compartment trim cover inner lh

5. Remove rear shock absorber with coil spring

Support the rear axle beam with jack.

Remove the 2 nuts and bolt.

...