Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Cruise control system / How to proceed with troubleshooting

Toyota Corolla (E120): How to proceed with troubleshooting

1 Vehicle brought to workshop

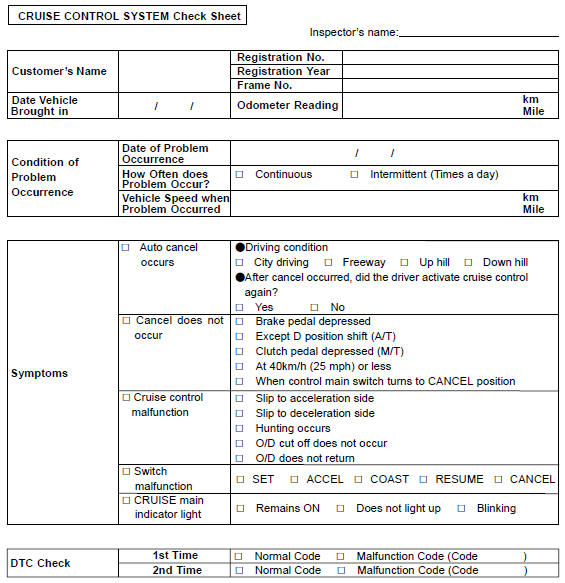

2 Customer problem analysis

3 Check and clear dtc

4 Problem symptom confirmation

5 Symptom simulation

6 Dtc check

7 Dtc chart

8 Problem symptoms table

9 Circuit inspection

10 Identification of problem

11 Parts inspection

12 Repair

13 Confirmation test

End

Customer problem analysis check

Other materials:

Maintenance requirements

To ensure safe and economical driving, day-to-day care and regular maintenance

are essential. It is the owner’s responsibility to perform regular checks. Toyota

recommends the following maintenance:

General maintenance

General maintenance should be performed on a daily basis. This can be don ...

Circuit description

When driving uphill under cruise control, in order to reduce the number of

shifting due to on–off overdrive

operation and to provide smooth driving, when down shifting in the

electronically controlled transmission occurs,

a signal to prevent upshift until the end of the uphill slope is sent ...

Toyota Safety Sense 3.0 software

update

It is necessary to enter a

connected services contract,

provided by Toyota, to

use these functions. For

details, contact your Toyota

dealer.

WARNING

■For safe use

When the Toyota Safety Sense

3.0 software is updated, the operating

methods of functions may

change. Using this system without

knowing ...