Toyota Corolla (E120): System description

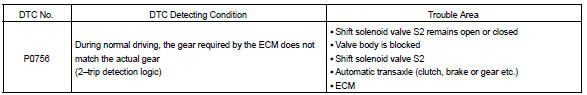

The ecm uses signals from the vehicle speed sensor and crankshaft position sensor to detect the actual gear position (1st, 2nd, 3rd or o/d gear).

Then the ecm compares the actual gear with the shift schedule in the ecm memory to detect the mechanical trouble of the shift solenoid valves, the valve body or automatic transaxle (clutch, brake or gear etc.).

Monitor description

The ecm commands gear shifts by turning the shift solenoid valves ”on/off”. According to the input shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ecm detects the actual gear position (1st, 2nd, 3rd or o/d gear position). When the gear position commanded by the ecm and the actual gear position are not same, the ecm illuminates the mil.

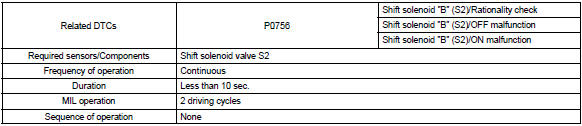

Monitor strategy

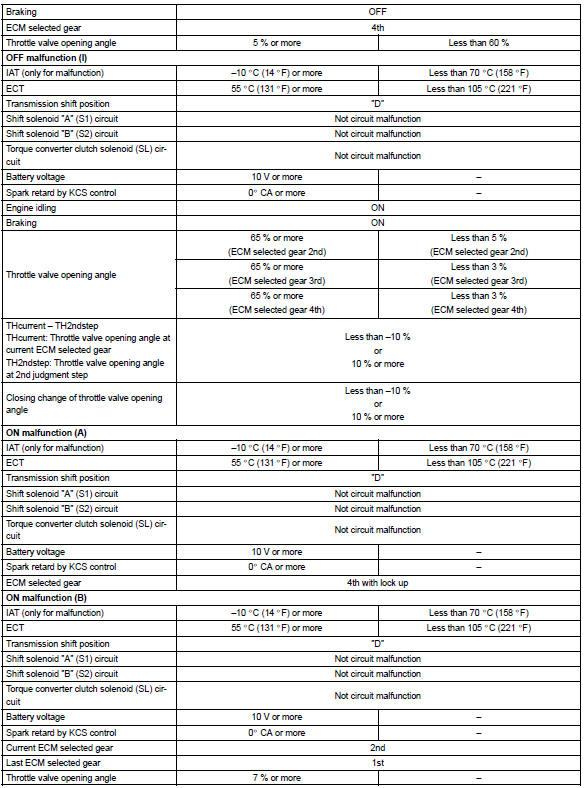

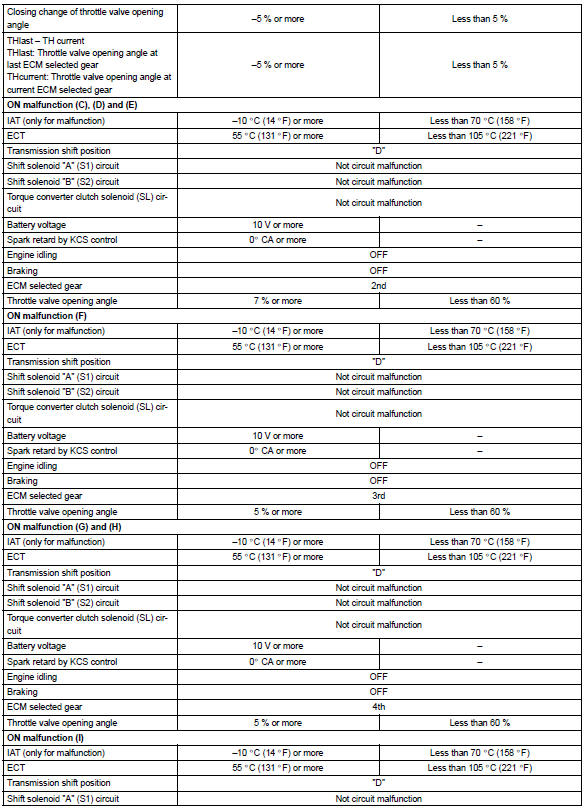

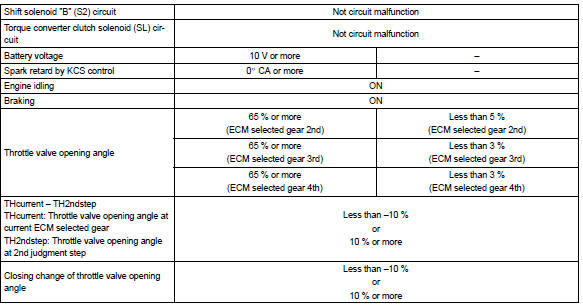

Typical enabling conditions

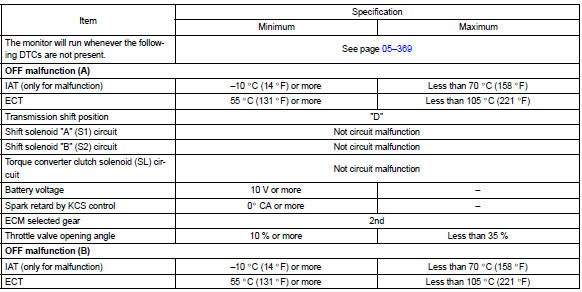

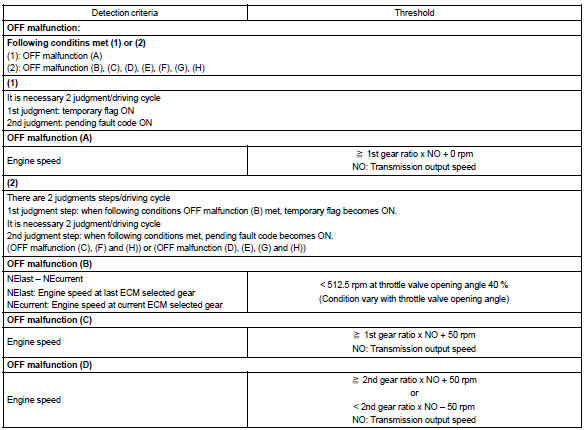

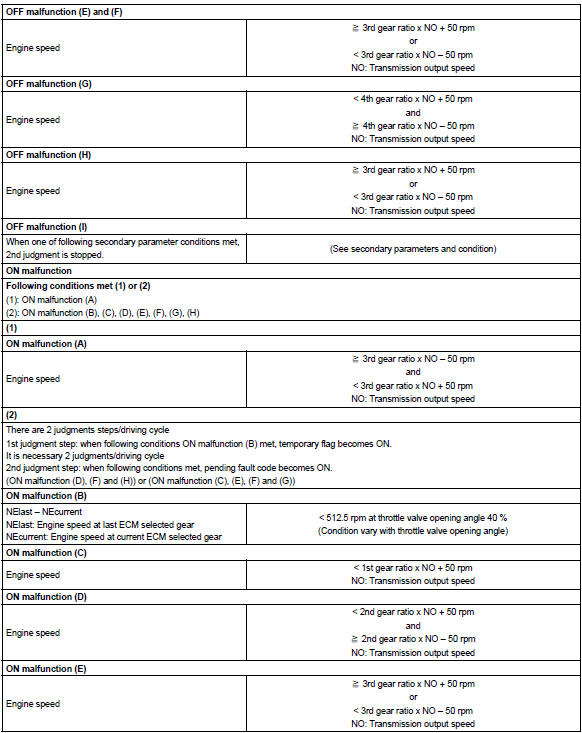

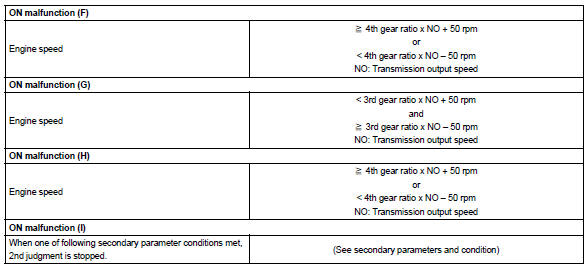

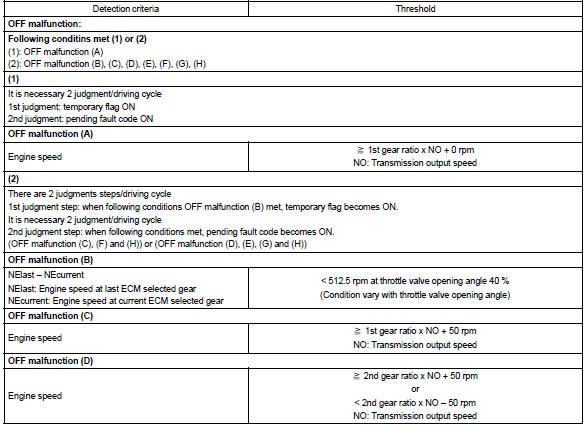

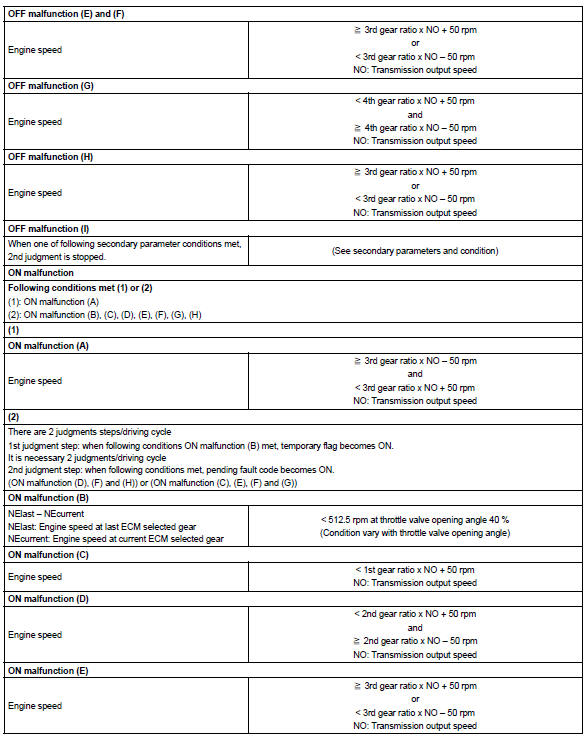

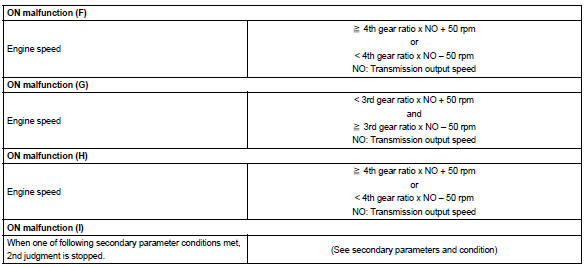

Typical malfunction thresholds

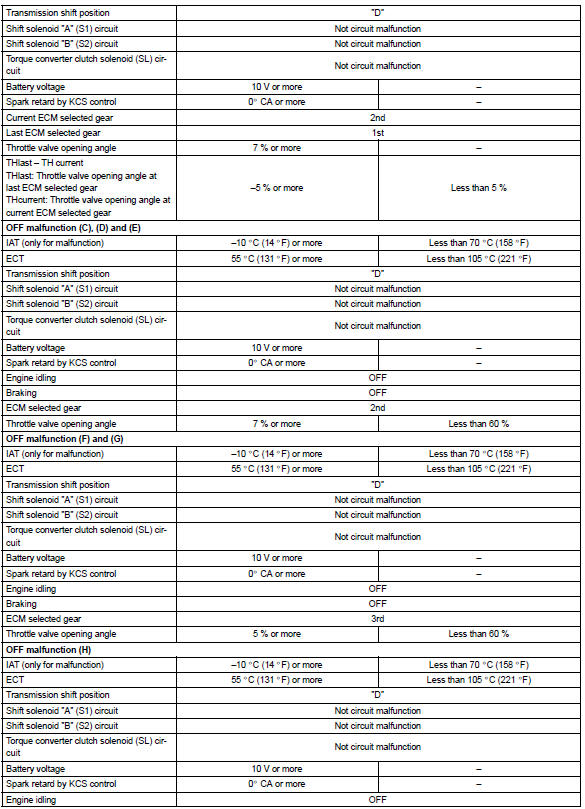

Typical malfunction thresholds

Other materials:

Inspection procedure

Hand–held tester:

1 Perform active test by hand–held tester(operation of circuit

opening relay)

Connect the hand–held tester to the dlc3.

turn the ignition switch on and push the hand–held tester main

switch on.

select the item ”diagnosis / enhanced obd ii / active ...

Using the storage features

List of storage features

1 Glove box

2 Bottle holders

3 Console box

4 Cup holders

CAUTION

■Items that should not be left in the storage spaces

Do not leave glasses, lighters or spray cans in the storage spaces, as this

may cause the following when cabin temperature becomes high: ...

Inspection and adjustment procedure

1 Tire valve

2 Tire pressure gauge

1 Remove the tire valve cap.

2 Press the tip of the tire pressure gauge onto the tire valve.

3 Read the pressure using the gauge gradations.

4 If the tire inflation pressure is not at the recommended level, adjust the pressure.

If you add too much air, pres ...