Toyota Corolla (E120) 2002–2008 Repair Manual / Starting & charging / Starting system

Toyota Corolla (E120): Starting system

Inspection

1. Inspect starter assy

Notice

: these tests must be performed within 3 to 5 seconds to prevent burnout of the coil.

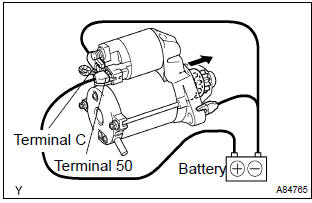

- perform the pull–in test.

- Remove the nut, then disconnect the lead wire from terminal c.

- Connect the battery to the starter repair service kit as shown in the illustration. Check that the clutch pinion gear is extended.

If the clutch pinion gear is not extended, replace the starter repair service kit.

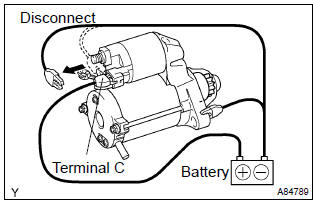

- Perform the hold–in test.

- Disconnect the negative (–) lead from terminal c

with the lead wire disconnected from terminal c.

Check that the clutch pinion gear remains extended.

If the clutch pinion gear returns, replace the starter repair service kit.

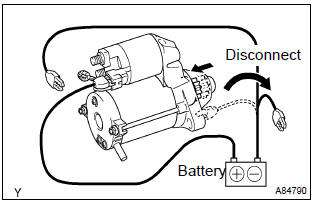

- Check the clutch pinion gear returns.

- Disconnect the negative (–) lead from the starter body. Check that the clutch pinion gear returns.

If the clutch pinion gear does not return, replace the starter repair service kit.

- Perform the no–load performance test.

- Connect the lead wire to terminal c with the nut.

Make sure that the lead is not grounded.

Torque: 10 nvm (102 Kgf·cm, 7 ft·lbf)

- Clamp the starter in a vise.

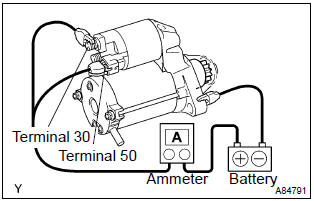

- Connect the battery and an ammeter to the starter as shown in the illustration.

- Check that the starter rotates smoothly and steadily

with the clutch pinion gear extended. Check that the

ammeter reads the specified current.

Specified current: 90 a or less at 11.5 V

If the current is not as specified, replace the starter repair service kit.

2. Inspect starter relay assy

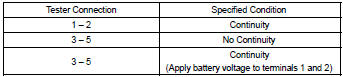

- Check the continuity.

- Using an ohmmeter, check for continuity between each terminal.

Specified condition:

If the result is not as specified, replace the starter relay.

Other materials:

Emergency Driving Stop System

The emergency driving stop

system is a system which

automatically decelerates

and stops the vehicle within

its lane if the driver

becomes unable to continue

driving the vehicle, such as

if they have suffered a medical

emergency, etc.

During LTA (Lane Tracing

Assist) control, if the system

does not ...

Circuit description

The park/neutral position switch detects the shift lever position and sends

signals to the ecm.

Monitor description

The park/neutral position switch detects the gearshift position and sends a

signal to the ecm.

For security, the park/neutral position switch detects the gearshift positio ...

Fuel consumption information

Fuel consumption information

can be displayed on the

audio system screen.

System components

Audio system screen

Consumption

■ Trip information

1. Select on the main menu.

2. Select "Trip information".

If a screen other than "Current" is

displayed, select "Current".

The image is an example ...