Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / ABS with EBD system / Right/Left rear speed sensor circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: start the inspection from step 1 in case of using the hand–held tester and start from step 2 in case of not using the hand–held tester.

1 Read value of hand–held tester(skid control sensor)

- Check that there is no difference between the speed value output from

the speed sensor displayed

by the hand–held tester and the speed value displayed by the speedometer

when driving the vehicle.

Ok: there is almost no difference in the displayed speed value.

Hint

: there is tolerance of ± 10 % in the speedometer indication.

2 Inspect skid control sensor

- Disconnect the skid control sensor connector.

- measure resistance between terminals 1 and 2 of the skid

control sensor connector.

Ok: resistance: 2.2 Kw or less

- measure resistance between each of terminals 1 and 2 of

skid control sensor connector and body ground.

Ok: resistance: 1 mw or higher

Notice

: check the speed sensor signal last

3 Check harness and connector(skid control sensor – skid control ecu)

- Check for open and short circuit in harness and connector between each skid control sensor and skid control ecu

4 Inspect sensor and sensor rotor serrations

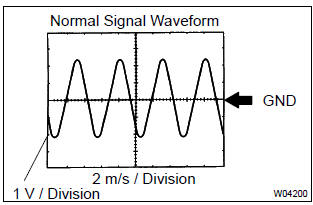

(Reference) inspection using oscilloscope

- connect the oscilloscope to the terminals rr+ – rr– and rl+ – rl– of the skid control ecu.

- drive the vehicle at about 30 km/h (19 mph), and check the signal waveform.

Hint

:

- as the vehicle speed (wheel revolution speed) increases, a cycle of the waveform becomes shorter and the fluctuation in the output voltage becomes greater.

- When noise is identified in the waveform on the oscilloscope, error signals are generated due to the speed sensor rotor’s scratches, looseness or foreign matter deposited on it.

5 Inspect sensor installation

- Check the sensor installation.

Ok: there is no clearance between the sensor and rear axle carrier.

Notice

: check the speed sensor signal last

6 Inspect skid control sensor tip

- Remove the skid control sensor .

- check the sensor tip.

Ok: no scratches or foreign objects on the sensor tip.

Notice

: check the speed sensor signal last

7 Inspect sensor rotor

- Check the sensor rotor serrations.

Ok: no scratches, missing teeth or foreign objects.

Notice

: check the speed sensor signal last

Check and replace brake actuator assy

Notice

: do not reuse skid control sensor.

Other materials:

Supplemental restraint system

Preparation

Sst

Recomended tools

Equipment

...

Standard bolt

How to determine bolt strength

Specified torque for standard bolts

How to determine nut strength

*: Nut with 1 or more marks on one side surface of the nut.

Hint:

use the nut with the same number of the nut strength classification or the

greater than the bolt strength classificati ...

Replacement

Hint:

for parking brake cable assy no.2, Perform the same procedure to the parking

brake cable assy no.3.

1. Remove rear wheel

2. Remove rear brake drum sub–assy

3. Remove rear brake automatic adjust lever lh

4. Remove front brake shoe

sst 09718–00010

5. Remove parking brake sho ...