Toyota Corolla (E120): Replacement

1. Work for preventing gasoline from spilling out

2. Remove cylinder head cover no.2

- Remove the 2 nuts, 2 clips and cylinder head cover.

3. Disconnect ventilation hose

- Disconnect the ventilation hose from the cylinder head cover.

4. Disconnect engine wire

- Disconnect the 4 fuel injector connectors.

- remove the 3 wire harness clamps from the clamp brackets.

5. Remove efi fuel pipe clamp

- Remove the efi fuel pipe clamp.

6. Disconnect fuel tube sub–assy

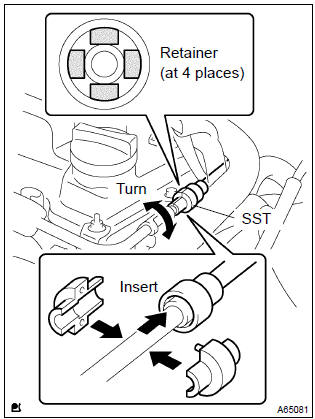

- Using a sst, disconnect the fuel tube.

Sst 09268–21010

- assemble the sst to the connection as shown.

- Turn the sst, align the retainers inside the connector with the sst chamfered parts and insert the sst into the connector.

- Slide the sst and the connector together towards the fuel tube assembly.

Notice

:

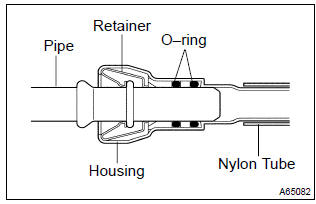

- check if there is dirt mud on the pipe and around the connector before disconnecting them and clean the dirt away.

- Do not bent, fold and rotate the nylon tube.

- When the connector and the pipe are stuck, push and pull the connector to free to disconnect and pull it out.

- Prevent the disconnected pipe and connector from damaging and mixing foreign objects by covering them with a vinyl bag.

7. Remove fuel delivery pipe sub–assy

- Remove the 3 bolts and fuel delivery pipe together with the 4 fuel injectors.

Notice

: be careful not to drop the fuel injectors when removing the fuel delivery pipe.

- Remove the 2 spacers from the cylinder head.

8. Remove fuel injector assy

- Pull out the 4 fuel injectors from the fuel delivery pipe.

9. Install fuel injector assy

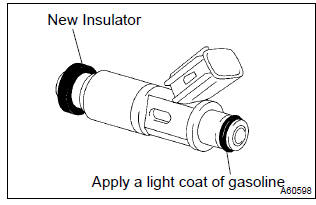

- Install a new insulator to the each fuel injector.

- apply a light coat of spindle oil or gasoline to a new o– ring, and install it to the each fuel injector.

Notice

: never use engine, gear or brake oil.

- Apply a light coat of spindle oil or gasoline on the place where the fuel delivery pipe touches on the o–ring.

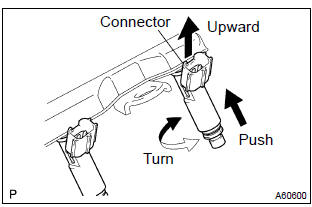

- while turning the fuel injector clockwise and counterclockwise, and push it to the fuel delivery pipe.

Notice

:

- be careful not twist the o–ring.

- After installing the fuel injectors, check that they turns smoothly. If the fuel injector does not, reinstall it with a new o–ring.

10. Install fuel delivery pipe sub–assy

- Install the 2 spacers to the cylinder head.

- install the fuel delivery pipe together with the 4 fuel injectors

with the 3 bolts.

Torque:

bolt a 19 nvm (194 kgfvcm, 14 ftvlbf) bolt b 9.0 Nvm (92 kgfvcm, 80 in.Vlbf)

Notice

:

- be careful not drop the fuel injectors when installing the fuel delivery pipe.

- Check that the fuel injectors rotate smoothly after installing the fuel delivery pipe.

11. Connect fuel tube sub–assy

- Connect the fuel tube to the fuel delivery pipe.

Notice

:

- check if there is any damage or foreign objects on the connected part of the fuel tube.

- After connecting, check if the fuel tube and the connector are securely connected by pulling them.

12. Install cylinder head cover no.2

- Install the cylinder head cover with the 2 nuts and 2 clips.

Torque: 7.0 Nvm (71 kgfvcm, 62 in.Vlbf)

13. Check fuel leak

Other materials:

Fuel

Preparation

Sst

Recomended tools

Ssm

Equipment

...

General information

1. Basic dimensions

(a) there are two types of dimensions in the diagram.

(1) (Three-dimensional distance)

straight-line distance between the centers of two

measuring points.

(2) (Two-dimensional distance)

horizontal distance in forward/rearward direction

between the centers o ...

If you think something is wrong

If you notice any of the following symptoms, your vehicle probably needs adjustment

or repair. Contact your Toyota dealer as soon as possible.

Visible symptoms

● Fluid leaks under the vehicle.

(Water dripping from the air conditioning after use is normal.)

● Flat-looking tires or u ...