Toyota Corolla (E120) 2002–2008 Repair Manual / Heater & air conditioner / Air conditioning system / On–vehicle inspection

Toyota Corolla (E120): On–vehicle inspection

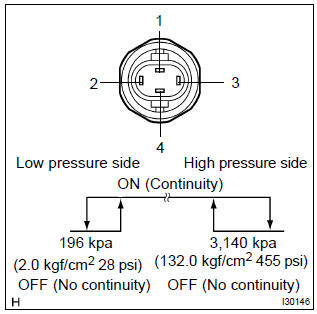

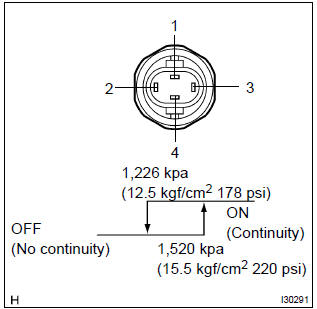

1. Inspect pressure switch no.1.

- Magnetic clutch control: inspect pressure switch operation.

- Set on the manifold gauge set.

- Connect the positive (+) lead from the ohmmeter to terminal 4 and the negative (–) lead to terminal 1.

- Check continuity between terminals when refrigerant pressure is changed, as shown in the illustration.

If operation is not as specified, replace the pressure switch.

- Cooling fan control: inspect pressure switch operation.

- Connect the positive (+) lead from the ohmmeter to terminal 2 and the negative (–) lead to terminal 3.

- Check continuity between terminals when refrigerant pressure is changed, as shown in the illustration.

If operation is not as specified, replace the pressure switch.

2. Cooler compressor assy w/magnetic clutch

- connect the positive (+) lead from the battery to terminal and the negative (–) lead to the body ground.

- check that the magnetic clutch energized.

If operation is not as specified, replace the magnet clutch assy.

Other materials:

Vehicle information

This screen can be used to display the fuel consumption.

“Trip Information” or “Past Record” screen

Press “CAR” to display the “Trip Information” or “Past Record” screen.

Fuel consumption

■ Trip information

If the ‚ÄúTrip Information‚Äù screen does not appear, select ‚ ...

Listing the registered cellular phones

Select “List Phone” using .

The list of registered cellular phones will be displayed.

● Connecting the registered cellular phone to the audio system

1 Select the name of the cellular phone to be connected using

.

2 Select “Select” using .

● Deleting a registered cell ...

Inspection procedure

1 Check side squib(lh) circuit(airbag sensor assy center – front

seat airbag assy lh)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the front seat airbag assy ...