Toyota Corolla (E120): Inspection

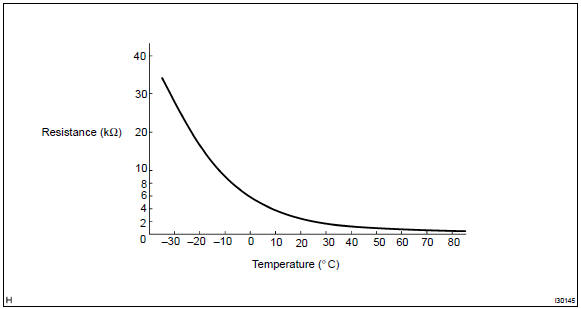

1. Cooler thermistor no.1

- Check resistance between terminals 1 and 2 of cooler

thermistor no. 1 At each temperature, as shown in the

chart.

Resistance:

If resistance value is not as specified, replace the sensor.

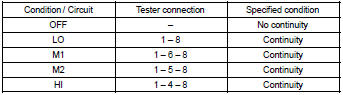

2. Cooler and accessory assy

- Inspect blower switch continuity.

If continuity is not as specified, replace the air conditioner control assy.

- inspect illumination operation.

Connect the positive (+) lead from the battery to terminal 2 and negative (–) lead to terminal 3 then check that the illuminations light up.

If there is bulb not light up, replace the bulb.

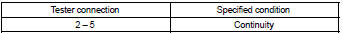

3. Cooler switch hole cover

- Inspect switch continuity.

Check the continuity between terminals while switch is pressed, as shown in the chart.

If continuity is not as specified, replace the cooler switch.

- inspect illumination operation.

Connect the positive (+) lead from the battery to terminal 4 and negative (–) lead to terminal 3 then check that the illuminations light up.

If operation is not as specified, replace the cooler switch.

- inspect indicator operation.

- Connect the positive (+) lead from the battery to terminal 2 and the negative (–) lead to terminal 1.

- Push the a/c button in and then check that the indicator lights up.

If operation is not as specified, replace the cooler switch.

- inspect dimming operation

- connect the positive (+) lead from the battery to terminal 2 and the negative (–) lead to terminal 1 while press the switch.

- Connect the positive (+) lead from battery to terminal 4 and then check that the indicator dims.

If operation is not as specified, replace the cooler switch.

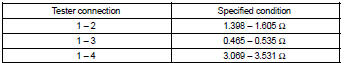

4. Blower resistor

- Measure resistance between terminals, as shown in the chart below.

If resistance is not as specified, replace the blower resistor.

5. Blower w/fan motor sub–assy

- Connect the positive (+) lead from the battery to terminal 2 and negative (–) to terminal 1, then check that the motor operation smoothly.

If operation is not as specified, replace the blower motor.

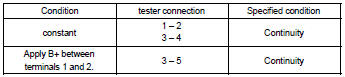

6. Heater blower motor relay assy

If continuity is not as specified, replace the heater blower motor relay.

7. Magnet–clutch relay

If continuity is not as specified, replace the magnet–clutch relay.

Other materials:

Emergency Driving Stop System

The emergency driving stop

system is a system which

automatically decelerates

and stops the vehicle within

its lane if the driver

becomes unable to continue

driving the vehicle, such as

if they have suffered a medical

emergency, etc.

During LTA (Lane Tracing

Assist) control, if the system

does not ...

If a warning light turns on or a

warning buzzer sounds

Calmly perform the following actions if any of the warning

lights comes on or flashes. If a light comes on or flashes, but

then goes off, this does not necessarily indicate a malfunction

in the system. However, if this continues to occur, have the

vehicle inspected by your Toyota dealer.

Actions to ...

Supplemental restraint system

Preparation

Sst

Recomended tools

Equipment

...