Toyota Corolla (E120) 2002–2008 Repair Manual / Heater & air conditioner / Refrigerant / On–vehicle inspection

Toyota Corolla (E120): On–vehicle inspection

1. Inspect refrigerant pressure with manifold gauge set

- this is a method in witch the trouble is located by using

a manifold gauge set. Read the manifold gauge pressure

when the these conditions are established.

Test conditions:

- temperature at the air inlet with the switch set at recirc is 30 – 35 °c (86 – 95 °f)

- engine running at 1500 rpm

- blower speed control switch at ”hi” position

- temperature control dial at ”cool” position a/c switch on

- fully open doors

- Normally functioning refrigeration system.

Gauge reading:

low pressure side:

0.15 – 0.25 Mpa (1.5 – 2.5 Kgf/cm2) high pressure side:

1.37 – 1.57 Mpa (14 – 16 kgf/cm2)

- Moisture present in refrigeration system.

|

Symptom |

Probable cause |

Diagnosis |

Remedy |

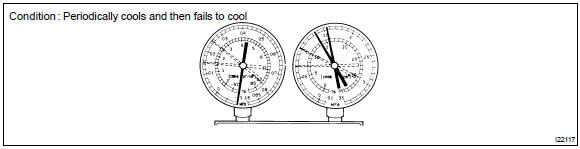

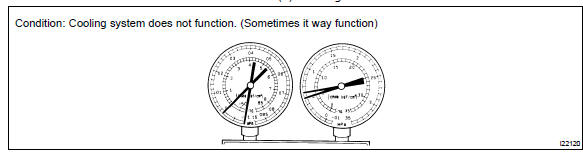

| During operation, pressure on low pressure side sometimes become a vacuum and sometime normal | Moisture in refrigerating system freezes at expansion valve orifice causing a temporary stop of cycle, however, when it melts, normal state is restored. |

|

|

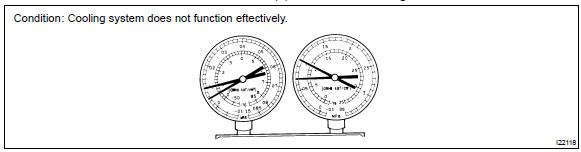

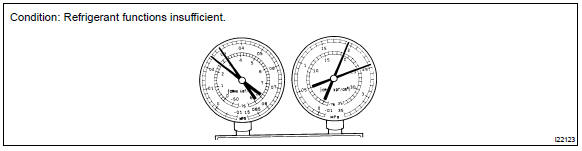

- Insufficient cooling

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Gas leakage in refrigeration system |

|

|

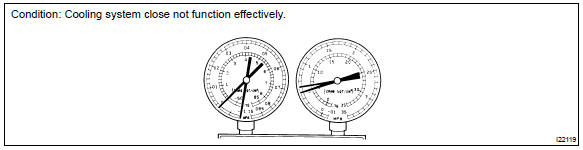

- Poor circulation of refrigerant

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Refrigerant flow obstructed by dirt in receiver | Receiver clogged | Replace condenser |

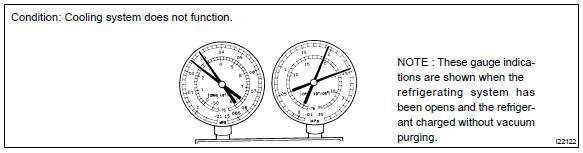

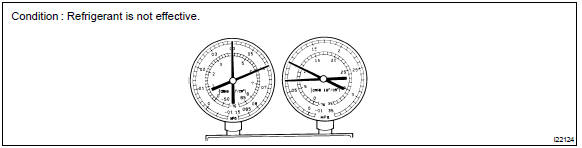

- Refrigerant does not circulate

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

|

Refrigerant does not circulate |

|

- Refrigerant overcharged or insufficient cooling of condenser

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

|

|

|

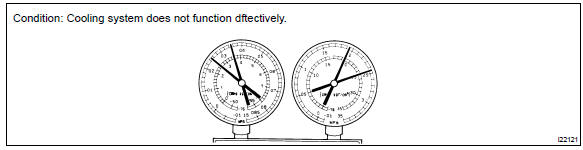

- Air present in refrigeration system

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Air entered in refrigerating system |

|

|

- Expansion valve improperly

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Trouble in expansion valve |

|

Check expansion valve |

- Defective compression compressor

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Internal leak in compressor |

|

Repair or replace compressor |

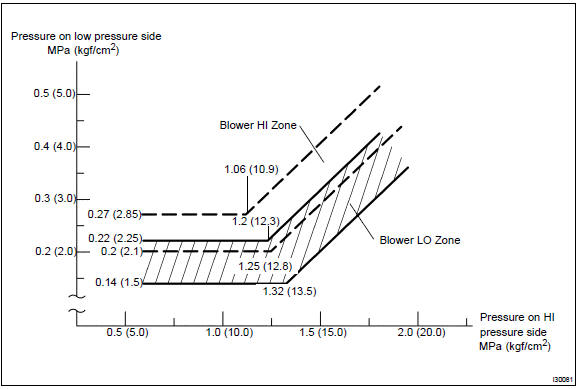

Gauge readings (reference)

Other materials:

Mechanical system tests

1. Perform mechanical system tests

Measure the stall speed.

The object of this test is to check the overall performance of the transaxle

and engine by measuring

the stall speeds in the d and r positions.

Notice:

Do the test at normal operating atf temperature 50 to 80 °c (122 to

...

How to proceed with troubleshooting

1 Vehicle brought to workshop

2 Customer problem analysis

3 Check and clear dtcs and freeze frame data

4 Problem symptom confirmation

Symptom does not occur: go to

step 5

Symptom occurs: go to step 6

5 Symptom simulation

6 Dtc check

There is no

output: go to step 7

There is outp ...

Checking and adding the

brake fluid

■ Checking fluid level

The brake fluid level should be

between the "MAX" and "MIN"

lines on the tank.

■ Adding fluid

1. Slide and lift up the rubber

strip to partly remove it as

shown.

2. Disconnect the claws and

remove the service cover.

3. Remove the reservoir cap.

4. Add brake fluid slowl ...