Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Combination meter / Malfunction in water temperature receiver gauge

Toyota Corolla (E120): Malfunction in water temperature receiver gauge

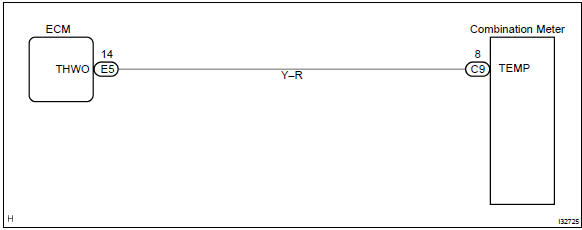

Wiring diagram

Inspection procedure

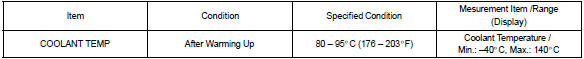

1 Read value of hand–held tester

- Check output value of ecm.

- Connect the hand–held tester to dlc3.

- Turn the ignition switch to on and push the hand–held tester main switch on.

- Select the data list mode on the hand–held tester.

2 Inspect combination meter assy

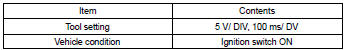

(Reference) inspection using oscilloscope

- check the input signal waveform.

- Remove the combination meter with connectors still connected.

- Connect the oscilloscope to the terminals c9–8 of combination meter assy and body ground.

- Start engine.

- Check the signal waveform.

3 Check harness and connector(between ecm and combination meter assy)

- Remove the combination meter.

- check the continuity between terminals 14 (thwo) of ecm and c9–8 of

combination meter connector.

Standard: there is continuity.

Check and replace ecm

Other materials:

Terminals of ecu

1. Inspect integration relay

Disconnect the connector and check the continuity of each terminal of

the disconnected connector.

Standard :

If the result is not as specified, the vehicle’s side may malfunction.

Reconnect the connector and check each terminal.

Standard:

If ...

Using a Bluetooth® Phone

The hands-free system is a function that allows you to use your cellular phone

without touching it.

This system supports Bluetooth®. Bluetooth® is a wireless data system that allows

the cellular phone to wirelessly connect to the hands-free system and make/receive

calls.

Before making a ph ...

Oxygen sensor monitor (front and rear o2s system)

Preconditions

The monitor will not run unless:

mil is off

drive pattern

connect the obd ii scan tool to the dlc3 to check monitor status

and preconditions.

Start the engine and allow it to idle for 2 minutes or more.

Drive the vehicle at 25 mph ...