Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Ecm power source circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

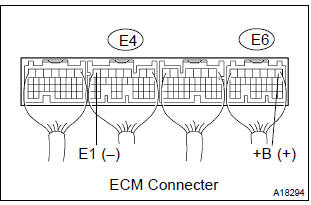

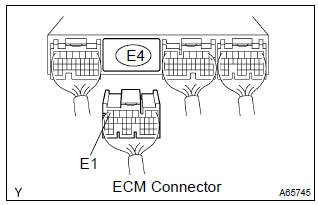

1 Inspect ecm(+b voltage)

- Turn the ignition switch on.

- measure the voltage between the terminals of the e4 and e6 ecm connectors.

Standard:

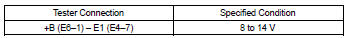

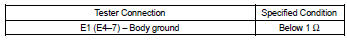

2 Check harness and connector(ecm – body ground)

- Disconnect the e4 ecm connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

- Reconnect the ecm connector

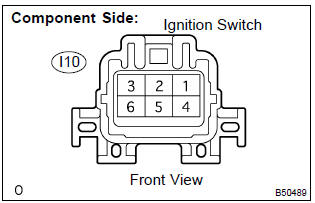

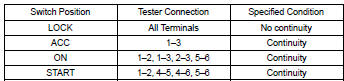

3 Inspect ignition or starter switch assy

- Disconnect the i10 ignition switch connector.

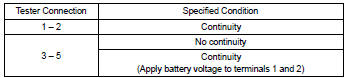

- check for continuity between the connector terminals shown in the chart below.

- Reconnect the ignition switch connector.

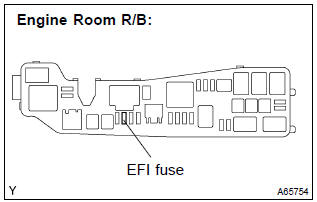

4 Check fuse(efi fuse)

- Remove the efi fuse from the engine room r/b.

- check for continuity in the efi fuse.

Standard: continuity

- reinstall the efi fuse.

5 Inspect efi relay

- Remove the efi relay from the engine room r/b.

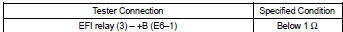

- check for continuity in the circuit efi relay.

Standard:

- Reinstall the efi fuse.

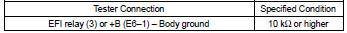

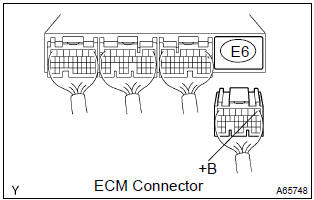

6 Check harness and connector(efi relay – ecm, efi relay – body ground)

- Check the harness and connector between the efi relay and ecm.

- Remove the efi relay from the engine room r/b.

- Disconnect the e6 ecm connector.

- Check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the ecm connector.

- Reinstall the efi relay.

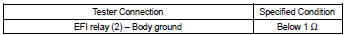

- check the harness and connector between the efi relay and body ground.

- Remove the efi relay from the engine room r/b.

- Check the resistance between the wire harness side connector and body ground.

Standard (check for open):

- Reinstall the efi relay.

Check and repair harness and connector (terminal +b of ecm – battery positive terminal)

Other materials:

Bluetooth® device registration status

1 Display the “Bluetooth* Setup” screen.

*: Bluetooth is a registered trademark of Bluetooth SIG, Inc.

2 Select the device.

3 Select “Device Info”.

4 Following screen is displayed:

1 Device Name

2 Change connection method

3 Bluetooth® Address

4 Display your telephone number

The n ...

Bluetooth® phone message function

Received messages can be forwarded from the connected Bluetooth® phone, enabling

checking and replying using the multimedia system.

Depending on the type of Bluetooth® phone connected, received messages may not

be transferred to the message inbox.

If the phone does not support the message fu ...

Maintenance requirements

To ensure safe and economical driving, day-to-day care and regular maintenance

are essential. It is the owner’s responsibility to perform regular checks. Toyota

recommends the following maintenance:

General maintenance

General maintenance should be performed on a daily basis. This can be don ...