Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position sensor ”a”

circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

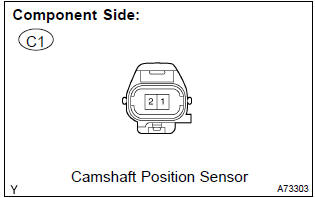

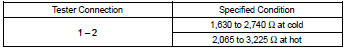

1 Inspect camshaft position sensor(resistance)

- Measure the resistance between the terminals of camshaft position sensor connector.

Standard:

Notice

: ”cold” and ”hot” shown above mean the temperature of the coils themselves. ”Cold” is from –10 c (14 f) to 50 c (122 f) and ”hot” is from 50 c (122 f) to 100 c (212 f).

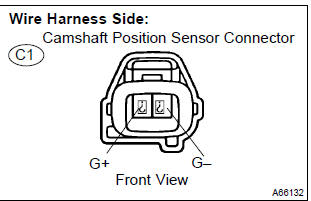

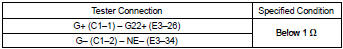

2 Check harness and connector(camshaft position sensor – ecm)

- Disconnect the c1 camshaft position sensor connector.

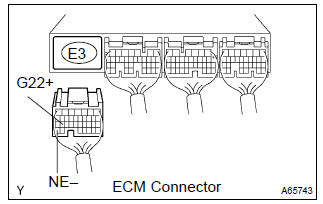

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

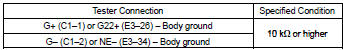

Standard (check for open):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the camshaft position sensor connector.

3 Check sensor installation(camshaft position sensor)

- Check the camshaft position sensor installation.

4 Check camshaft timing gear assy(teeth of plate)

- Check the teeth of the signal plate.

Replace ecm

Other materials:

Inspection procedure

1 Check side squib(lh) circuit(airbag sensor assy center – front

seat airbag assy lh)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the front seat airbag assy ...

Circuit description

The vehicle equipped with abs detects a vehicle speed using the stability

control ecu and wheel speed

sensor. This sensor monitors a wheel rotation speed and sends the signal to the

ecu.

The stability control ecu converts these wheel speed signals into a 4–pulse

signal and outputs it to ...

Using the key (vehicles

without a smart key system

and with a wireless

remote control function)

Releasing

To release the key, press the button

Folding

To stow the key, press the button

then fold the key.

Using the mechanical key

(vehicles with a smart key

system)

To take out the mechanical key,

slide the release button and take

the key out.

The mechanical key can only be

inserted in o ...