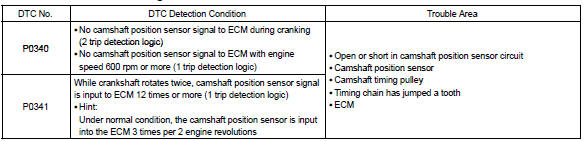

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position sensor ”a”

circuit / Circuit description

Toyota Corolla (E120): Circuit description

The camshaft position sensor (g22+ signal) consists of a magnet, iron core and pickup coil.

The g22+ signal plate has 3 teeth on its outer circumference and is installed on the camshaft timing pulley.

When the camshafts rotate, the protrusion on the signal plate and the air gap on the pickup coil changes, causing fluctuations in the magnetic field and generating an electromotive force in the pickup coil.

The ne+ signal plate (crankshaft timing pulley) has 34 teeth and is installed to the crankshaft. The ne+ signal sensor generates 34 signals at every engine revolution. The ecm detects the crankshaft angle and the engine revolution based on the ne+ signals, and the cylinder and the angle of the vvt based on the combination of the g22+ and ne+ signals.

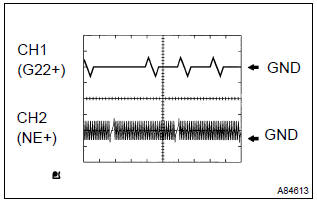

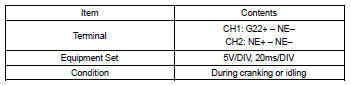

Reference: inspection using the oscilloscope.

Hint

: the correct waveform is as shown on the left.

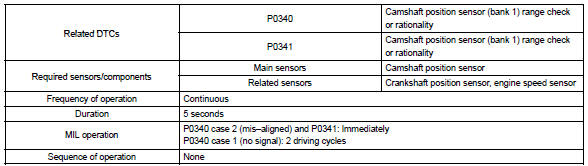

Monitor description

If there is no signal from the camshaft position sensor despite the engine revolving, or if the rotation of the camshaft and the crankshaft is not synchronized, the ecm interprets this as a malfunction of the sensor.

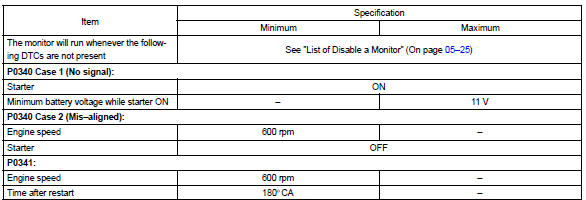

Monitor strategy

Typical enabling conditions

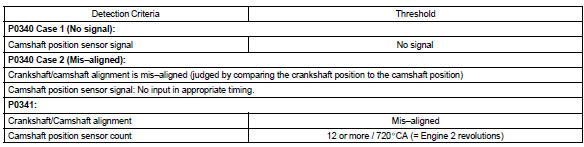

Typical malfunction thresholds

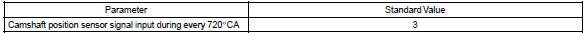

Component operating range

Wiring diagram

Refer to dtc p0335

Other materials:

Overhaul

Hint: components:

1. Remove front wheel

2. Disconnect front stabilizer link assy lh

Remove the nut and disconnect the front stabilizer link

assy lh from the shock absorber assy front lh.

Hint:

if the ball joint turns together with the nut, use a hexagon (6 mm)

wrench to hold the st ...

Inspection procedure

Hint:

read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is

useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the ...

If your vehicle overheats

The following may indicate that your vehicle is overheating.

● Vehicles without a multi-information display: The high engine coolant temperature

warning light comes on or a loss of power is experienced.

Vehicles with a multi-information display: The engine coolant temperature gauge&n ...