Toyota Corolla (E120): Adjustment

1. Headlight aim only

- place the vehicle in the following conditions.

- The area around the headlight is not deformed.

- The vehicle is parked on a level surface.

- Tire inflation pressure is in the specified value .

- A driver is in the driverŌĆÖs seat and the vehicle is in a state ready for driving (with a tank full).

- The vehicle has been bounced several times.

- check the headlight aiming.

- Prepare a thick white paper.

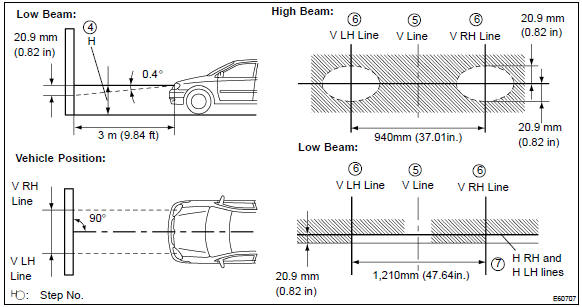

- Stand the paper perpendicular to the ground at the position 9.84 Ft away from the headlights.

- Ensure that the center line of the vehicle and the paper face forms a 90ŌĆōdegree angle as shown in the illustration.

- Draw a horizontal line (h line) on the paper, showing where the headlights should strike.

- Draw a vertical line (v line) to where the center line of the vehicle is to be.

- Draw 2 vertical lines to where the both headlights should strike (v rh and v lh lines).

- Draw a horizontal line (by connecting the both low beam center marks) to where the headlights should strike (h rh and h lh lines).

- Take appropriate measures to prevent any influence of other lights.

- Set the headlights leveling position to ŌĆØ0ŌĆØ position and adjust the angle of the headlight axis.

Hint

: the h rh and h lh line is 0.4┬░ Below the horizontal line (h line) of the light axis.

- Start the engine.

- Turn the headlights on.

- Check that the headlights properly strike the position shown in the illustration.

- If not, adjust the lights in the vertical direction.

Hint

:

- as shown in the illustration, adjust each aim of the rh and lh lights.

- When adjusting the headlight aim in the veatical direction: using adjusting bolt, adjust the headlight aim to be within the specified range.

Hint

: the optical aim moves upward when turning a screwdriver clockwise, while it moves downward when turning a screwdriver counterclockwise.

Other materials:

Selecting wheel set (vehicles

with a tire pressure

warning system)

Your vehicle is equipped with a

tire pressure warning system

with a function to register two

sets of ID codes. This allows for

registration of a second wheel

set, for example a winter set.

The wheel set can be changed

only if a second wheel set has

been registered to the system. If

a second wheel s ...

Inspection procedure

1 Check operation(starter)

Check that the starter operates normally and that the engine starts.

2 Input signal check

See input signal check on page 05ŌĆō745.

check the indicator light when shifting into except d position.

Ok:

the indicator light goes off when shifting ...

How to scroll

: Select to scroll to the next or

previous page.

: If

appears to the right of titles, the

complete titles are too long for the display. Select this button to scroll the title.

Turn the ŌĆ£TUNE/SCROLLŌĆØ knob to move the cursor box to select a desired item from

the list, and press the Ō ...